Overview

Essential details

Type:

Gluing Machine

Applicable Industries:

Machinery Repair Shops, Food & Beverage Factory, Restaurant, Printing Shops, Food & Beverage Shops, Other, Advertising Company

Showroom Location:

Egypt, Italy, Morocco, Algeria, South Africa

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Warranty of core components:

1 Year

Core Components:

Engine, Motor

Condition:

New

Application:

Beverage, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles

Packaging Type:

Cartons, case

Packaging Material:

Wood

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

380V

Place of Origin:

Zhejiang, China

Brand Name:

Printyoung

Dimension(L*W*H):

13*1.8*1.4

Weight:

3500 KG

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Paper Material:

210-600g/m² paperboard;E corrugated board

Max. Liner speed:

0-300m/min continuous adjustment

Feeding way:

Automatic feeding

Way of folding:

single side gluing,pre-fold, Crash lock bottom

Glue Material:

Cold glue

After Warranty Service:

Video technical support, online support, Spare parts, Field maintenance and repair service

Local Service Location:

Egypt, Italy, Morocco, Algeria, South Africa

Marketing Type:

New Product 2020

After-sales Service Provided:

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, online support

Certification:

CE

Packaging & delivery

Packaging Details

wood case

Port

Ningbo and Shanghai

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 45 To be negotiated

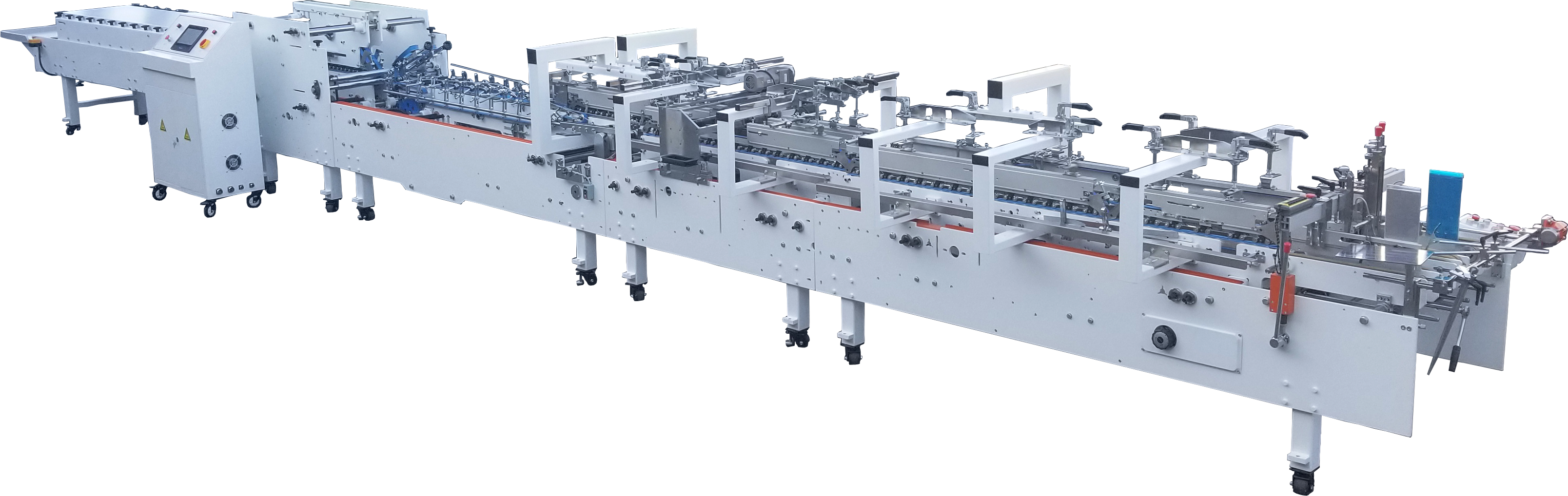

ZH-700D automatic folder gluer

Features

1.This machine is a fully automatic box gluer 2.Press table with waiting function 3.Wireless remote control 4.Take into account

both cardboard and E corrugated 5.Independent electrical box 6.There is a pre-pressure output part 7.Three gun cold glue spray

system 8.Plasma surface treatment

Technical Parameters

Configuration

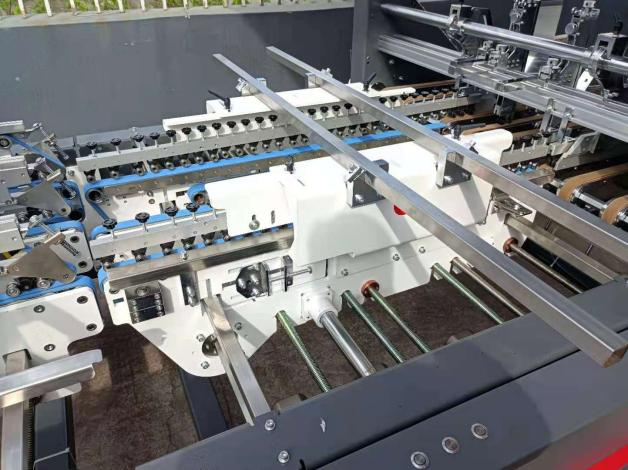

Paper Feeding Section

Equipped with three output knives, adjust the asymmetric length according to the actual sample The embossing power guide wheel

guides the paper output belt, and there are baffles on the left and right sides, which can be moved left and right according to

the product style. The vibrating device cooperates with the motor to feed paper quickly, easily and continuously automatically

Aligner section

The paper board sent from feeder section will be corrected by aligner section to ensure transmission accurately. Pressing drive

pressure can be adjusted up and down to accommodate different paper board thickness.