Overview

Essential details

Applicable Industries:

Hotels, Manufacturing Plant, Home Use, Food Shop, Printing Shops, Energy & Mining, Other, Advertising Company

Showroom Location:

Egypt, Italy, Algeria, South Africa, Morocco

Condition:

New

Machine Type:

Bag Forming Machine

Bag Type:

Shopping Bag

Material:

Paper

Computerized:

Yes

Place of Origin:

China

Brand Name:

Printyoung

Model Number:

SBR-330

Voltage:

380V

Dimension(L*W*H):

L 8800 mm * W 2500 mm * H 1900 mm

Weight:

6500 KG

Warranty:

1 Year

Key Selling Points:

Easy to Operate

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, Engine

Max Speed:

180 pcs/min

Width of Paper roll:

320-930 mm

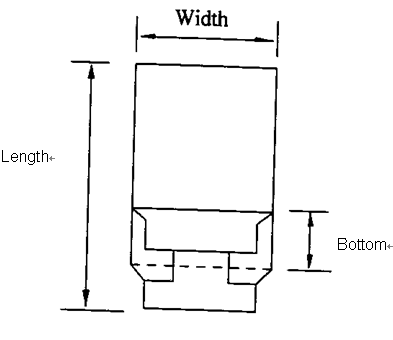

Length of Bag:

225-470 mm

Width of Bag:

150-330 mm

Width of Bag Bottom:

.60-160 mm

After Warranty Service:

Video technical support, online support, Spare parts, Field maintenance and repair service

Local Service Location:

Egypt, Italy, Morocco, Algeria, South Africa

After-sales Service Provided:

online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:

CE

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

wooden case

Port

Shang Hai

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 45 To be negotiated

SBR-330 Automatic Paper bag making machine

Features

1.Adjustable roll to square bottom bag making machine

2.Introduce In-touch screen human-machine interface, easy for correction and fine adjustment. Alarm and working status can be displayed in screen on-line, easy for operation and maintenance.

3.Equipped with PLC for centralized control system and SICK photocell for correction, tracking the printed material accurately, minimize the adjustment and preset time, increase the production efficiency.

4.Human oriented security protection, whole housing design, ensure the safety of operator.

5.Physiosis roller hydraulic material loading system with chuck, hydraulic up/down system

6.Automatic constant tension control for unwinding, EPC web guider system, motor for material feeding with inverter, minimize the adjustment time for web alignment.

7.High speed oriented design ensure successful of production: within the suitable paper range, production capacity can reach 150~180pcs/min, even higher,which increases the unit production capacity and gets higher profit.

8.Original SCHNEIDER electric system, ensure better stability and reliability; perfect after sale service, trouble free for customer.

* Speed will be variable due to different glue quality and operator’s skill.

* Bag Dimension, Adhesive Quality, Operator Knowledge, Moisture, Type and Basis weight of Paper Can affect Machine Speeds.

Technical Parameters

Configuration

Unwind Section

(1) Separated single unwind rollstand with hydraulic lift device. (2) Physiosis roller for paper roll loading, the load arms are driven by two hydraulic cylinders separately, can be adjusted freely. (3) Magnetic powder brake and constant auto tension control for unwinding tension control. (4) EPC (electronic program control ) web guide system for material alignment.