Overview

Essential details

Applicable Industries:

Garment Shops, Manufacturing Plant, Printing Shops, Food & Beverage Shops

Showroom Location:

Egypt, Turkey, Viet Nam, Peru, Saudi Arabia, Indonesia, India, Russia, Thailand, Argentina, UAE, Sri Lanka, Bangladesh, South Africa, Ukraine, Uzbekistan, Malaysia, Morocco

Condition:

New

Machine Type:

Bag Forming Machine

Bag Type:

stationery bag, ornaments bag, garment Bag, food bag

Material:

Plastic

Computerized:

Yes

Place of Origin:

Zhejiang, China

Brand Name:

WITY

Model Number:

DRQ-KD

Voltage:

380V 50Hz

Dimension(L*W*H):

8800*1700*1800mm

Weight:

2500KG

Warranty:

one year

Key Selling Points:

High Productivity

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, Pump, Gearbox

After-sales Service Provided:

Engineers available to service machinery overseas

Suitable material:

Pp Opp Bopp Pe

Max. bag sealing width:

800mm

Max.Speed:

250pcs/min

Application:

Express bags

Processing Type:

Heat Sealing Hot Cutting

Color:

Green

Bag length:

500mm

Photocell:

Panasonic brand

Operation Language:

Chinese and English

After Warranty Service:

Video technical support, online support, Spare parts

Local Service Location:

Egypt, Turkey, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, India, Thailand, Malaysia, Morocco, Argentina, South Korea, Chile, UAE, Sri Lanka, Bangladesh, South Africa, Uzbekistan

Supply Ability

Supply Ability

30 Set/Sets per Month

Packaging & delivery

Packaging Details

Stretch film or wooden package

Port

Ningbo port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 45 To be negotiated

Video Description

Product Description

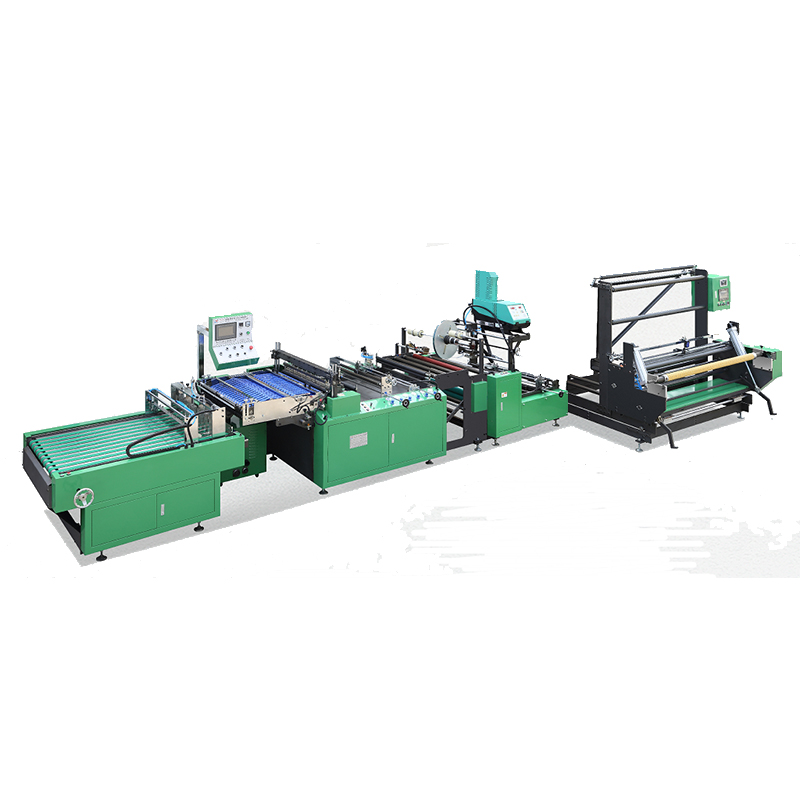

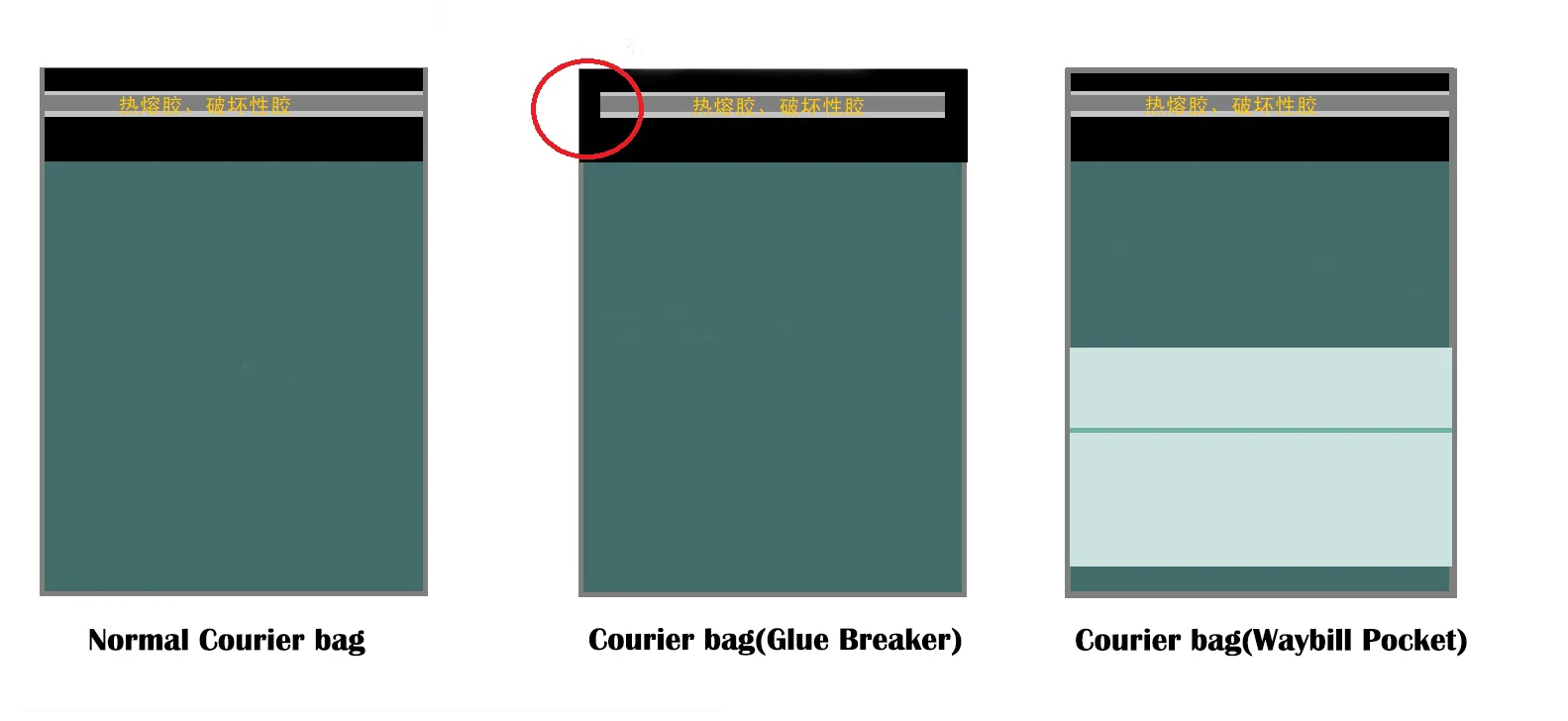

Fully automatic Courier bag making machine, specially designed for express bags, can be used in the production of recycled material express bags and new material express bags, such as SF and DHL high-end express bags with way-bill pocket(Optional).

Features

1.Touch screen operation and PLC control. 2.Servo motor for fixed length material feeding, imported photocell for print mark tracking. Precise register on printing pattern, automatic alarming and stop in case of photocell failure. 3.The main machine equipped with servo motor control. The retention time of sealing knife on silicone roller can be set according to the film thickness and requests of bags. 4.Automatic counting, take-out Clipper when setting quantity reached. 5.The Unwinder comes with two photocell for automatic web-guiding, automatic magnetic tension control, accurate folding. 6.Special sealing knife for express bag material, with the features of fast heating, firm and smooth sealing. 7.Film patching device for Way-bill pocket (Optional), special copper knife wedding device for film patching which can weld two layers of film firmly on the outside of the express bag. 8.10KG Hot melt glue device(Optional), coating glue evenly, with the function of automatic glue breaking.

Specification

Bag Details

Detailed Images

verified

verified