Overview

Essential details

Applicable Industries:

Manufacturing Plant, Printing Shops

Showroom Location:

Italy, Brazil, India, Spain

Condition:

New

Machine Type:

Bag Forming Machine

Bag Type:

Shopping Bag

Material:

Plastic, BOPP,CPP, PE ,etc

Computerized:

Yes

Place of Origin:

China

Brand Name:

WITY

Model Number:

DRQ-F600

Voltage:

220V/380V

Dimension(L*W*H):

8000x1300x1500mm

Weight:

1200KG

Warranty:

1 Year

Key Selling Points:

Automatic

After Warranty Service:

Video technical support, online support, Spare parts, Field maintenance and repair service

Local Service Location:

Turkey, Pakistan, Malaysia

After-sales Service Provided:

online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Max.unwinding width:

600mm

Max.unwinding diameter:

500mm

Speed:

40-100pcs/min

Max.bag making length:

550mm

Width:

70-500mm

Total power:

6KW

Supply Ability

Supply Ability

20 Set/Sets per Month

Packaging & delivery

Packaging Details

Stretch film packaging

Port

Ningbo port or Shanghai port

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 45 To be negotiated

Product Description

This machine is suitable for various kind of material such as BOPP,CPP , LDPE, HDPE,etc. It is the professional equipment which is used for making such special-shaped bags as flower bags,umbrella bags,tie bags,sandwich bags and so on.

Feature

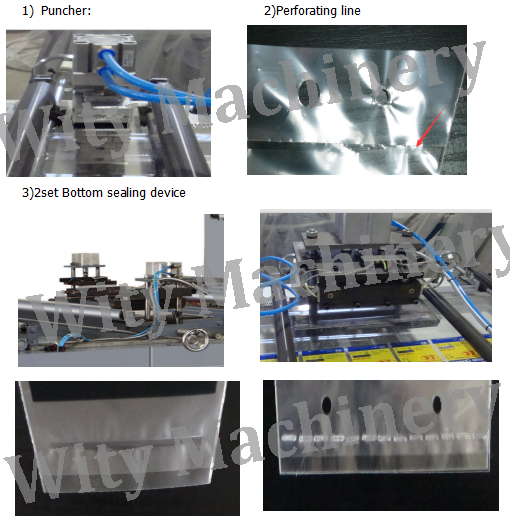

1) Touch screen operation,Panasonic brand PLC control,with the function of photocell tracking, fixed-length ,automatic counting, automatic stop of material breaking off,alarming when the color-mark is lost , automatic stop until the sealing in the highest position. 2) Adopt YASKAWA brand servo motor driving 3) Driving system adopts 5 sets of YASKAWA brand frequency inverter and Taiwan brand three-phase motor 4) Printed bags tracking use Taiwan brand photocell switch 5) Unwinding adopts air shaft, magnetic power brake control,with EPC control system. 6) Equipped with punching device, water-cooling device, dotted line spots breaking device, bottom sealing device, can meet the various shaped bags production 7) Adopt imported silica gel plate conveying

Specification

Details Images

verified

verified