Overview

Essential details

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Showroom Location:

None

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Ordinary Product

Warranty of core components:

3 years

Core Components:

Engine, Motor

Condition:

New

Place of Origin:

China

Weight:

200 kg

Warranty:

3 years

Weight (KG):

200 kg

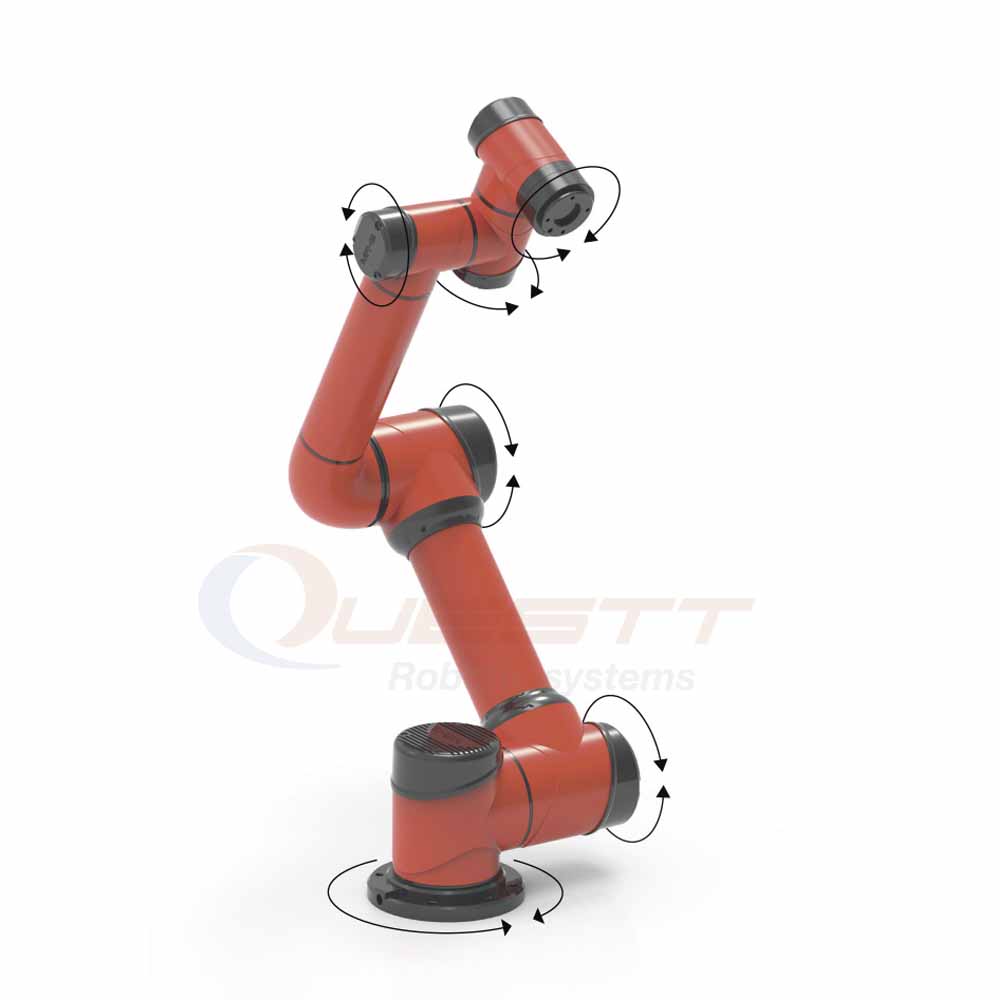

Axis:

6 axis

Payload:

6kgs

Armlength:

900mm

Control:

Automatic control panel

Certificate:

CE

Service:

Free training, online service or overseas serivice

Function:

Painting transporting welding cutting

Feature:

Very good quality

OEM:

OK

Packaging & delivery

Packaging Details

Wooden package

Port

Any

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 14 To be negotiated

Video Description

Hot selling Industrial programmable CNC robot arm 6 axis with low price arm robot 6dof for saleAutomatic System

What is an industrial robot?

Industrial robots are defined in accordance with ISO 8373. They are multi-joint robots or multi-degree-of-freedom robots for the industrial sector. An industrial robot is a machine that performs work automatically, and is a machine that realizes various functions by its own power and control ability. It can be commanded by humans or run in accordance with pre-programmed procedures, and modern industrial robots can also act according to the principles of artificial intelligence

We are specialized in customizing smart CNC automatic robotic system, with high quality and cheap price.

Introduction of KIKA robot/MR5 Collabotative robot/Epson Series Robot

Payload:6kgs, 20kgs, 50kgs etc.

Horizontal reach:1,405mm-2,291mm

Vertical reach:2,384-3,389mm

Repeatibility: ±0.05 mm

Weight: 74kgs,140kgs, 246kgs, 510kgs.

Kika series robot with different functions: In this page we only list Model-MR1400, a small model for your reference, if you need more models with other functions, please feel free to contact us.

KiKA robotic system MR1400 model is especially designed for Mig/Mag welding, which has high efficiency.

This series robot Small size light weight, is dedicated to arc welding robot, can realize the stable welding, obtain high precision welding path, shorten the welding cycle, extend the life of the pipe and cable At the same time SA series welding robot can flexible welding operations within the narrow space, can easily choose the ground installation mount inversion

Technical Parameters

| Model | MR1400 | |

| Payload | 6 KGS | |

| Max Working Radius | 1405 mm | |

| Arm Length | 2391 mm | |

| Number of Axis | 6 | |

Max speed | Axis1 | 150 °/S |

| Axis2 | 150 °/S | |

| Axis3 | 160 °/S | |

| Axis4 | 360 °/S | |

| Axis5 | 320 °/S | |

| Axis6 | 360 °/S | |

Max Operation Area | Axis1 | ±165° |

| Axis2 | +155° ~ -90° | |

| Axis3 | +70° ~ -200° | |

| Axis4 | ±170° | |

| Axis5 | ±120° | |

| Axis6 | ±360° | |

| Max moment Allowable Torque | Axis5 | 54 NM |

| Axis6 | 23 NM | |

| Weight | 140kg | |

| Position Repeatability | 0.05mm | |

| Working temperature | 0-45 ℃ | |

MR1400 Robotic Arm Standard Configuration List | |||

Control System | SMR1000 Controller + STEP Series Servo Driver | ||

Item No. | MR1400 | ||

Servo Motor Brand | TAMAGAWA MOTOR | ||

Length of power line | 5M | ||

Length of encoder lines | 5M | ||

Length of power supply line | 5M | ||

The teaching machine brand | Keba/SRTP1000 | ||

Length of teaching machine line | 5M | ||

Communication | Category | Name | Specifications |

Bus | EtherCAT bus | 1 piece | |

CANopen | 1 piece | ||

RS232/RS485 | 1 piece | ||

IO | digital input DI (Weidmuller) | 1 piece(16 road) | |

digital output DO (Weidmuller) | 1 piece(16 road) | ||

Others | Ethernet Standard Ethernet interface | 1 piece | |

Accessories | CD(Software, Project, electronic user manual) | ||

Remark | |||

Advantages of industrial robotics

1. stability and improve quality, ensure its homogeneity;

2. improve productivity, available 24 hours a day continuous production;

3. improving labor conditions, long-term work in a hazardous environment;

4. reduce the operation technique requirements;

5. reduce product modification replacement cycles, reduce investment in appropriate equipment;

6. realization of welding automation of batch products;

7. save floor space;

Applications of 6 axis robotic arm

Kika COMPACT robots are ideal for small parts assembly , dispensing , lab automation , medical device assembly , machine tending , material handling , packaging, electronics and many other applications.

This type is specially designed for Mig/Mag weldting industry.

verified

verified