Overview

Essential details

Place of Origin:

Japan

Brand Name:

HOTTY POLYMER

Plastic Modling Type:

Extruding

Processing Service:

Cutting, Packing

Material:

TPO

Process:

Co-extrusion

Color:

Black

MOQ:

100,000meters

Certificate:

ISO9001

Supply Ability

Supply Ability

5000 Meter/Meters per Day

Packaging & delivery

Packaging Details

TBD

Port

Tokyo

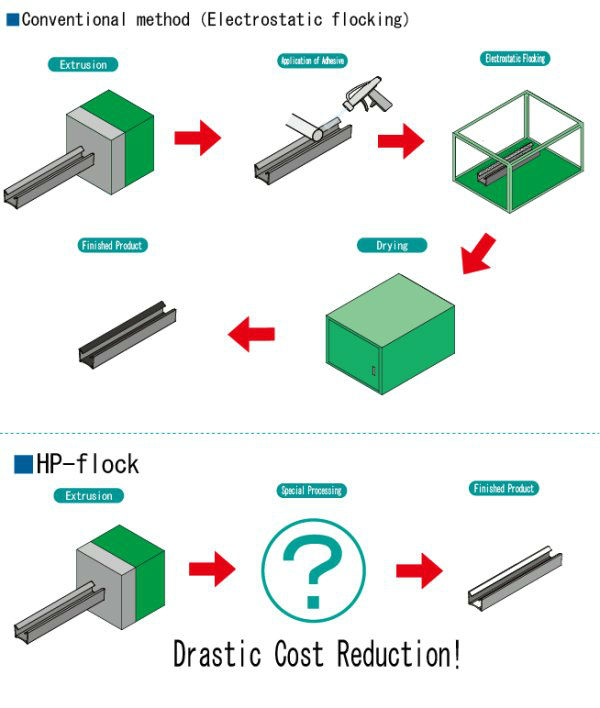

HP-flock Low cost flocking using special process technology instead of electrostatic processes for construction parts

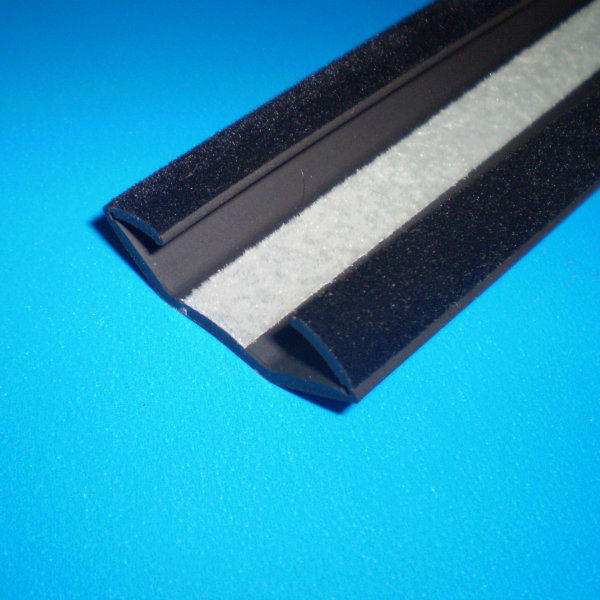

HP-flock is an innovative process for flocking using special processing. HP-flock extrusions can reduce the production cost and environmental loading. Electrostatic flocking extrusions cost much because they require the secondly processes and adhesives for electrostatic flocking. Unlike electrostatic flocking extrusions, HP-flock extrusions don't require masking and drying processes because they only use special processing. Many types of flocks can be selected, such as pile length, density, material and color. (Standard type:Nylon, 3.3dtx, 0.5mm). Multipoint processing and Sube-up(R) processing are possible at different points. As for base materials, various elastomers can be selected (TPO, TPS, EPDM, etc.). Please consult us for queries.

Features

Eco-friendly

HP-flock is environment friendly becasue it does not need adhesives.

Cost Performance

HP-flock can reduce the production cost because it uses special processing at in-line process.

Designability Weatherstrip for automobile, Glass run channel for automobile, Building gaskets,

Table edges, etc.

HP-flock can take a variety of designs because it can be colored.

Sliding Performance

Its sliding performance is as good as electrostatic flocking extrusions.

Applications

Weatherstrip for automobile, Glass run channel for automobile, Building gaskets,

Table edges, etc.

Comparison with conventional flocking process

verified

verified