Overview

Essential details

Place of Origin:

Anhui, China

Condition:

New

Repeatability (X/Y/Z) (mm):

±0.01

Table Travel (X) (mm):

1500

Table Travel (Y) (mm):

3000

Table Travel (Z) (mm):

180

Number of Axes:

5

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Hot Product 2021

Warranty of core components:

2 years

Cutting Accuracy(mm):

±0.1

Core Components:

PLC, Engine, Bearing, Gearbox, Motor

Brand Name:

ACCURL

Voltage:

380V 220V Optional

Rated Power:

7.5 KW

Dimension(L*W*H):

3880*2150*2000mm

Year:

2021

Warranty:

2 years

Weight (KG):

6500 KG

Applicable Industries:

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Home Use, Retail, Construction works

Key Selling Points:

High-accuracy

Showroom Location:

Morocco, Argentina, South Korea, Chile, Colombia, Romania, South Africa, Japan, Malaysia, Australia, Canada, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia

Type:

Water Jet Cutters

After-sales Service Provided:

Engineers available to service machinery overseas, online support, Video technical support

Model Number:

MAX-WJ-2515D

Gantry type:

Table

Effective Cutting area:

1500x3000mm

Ball screw & Linear guide rail:

HIWIN from TAIWAN

Major motor of pump:

Siemens from Germany

CNC controller:

AI, DST, DWG, DXF, DXP, LAS

Keyword:

Water Jet cnc Cutting Machine

Weight:

6500Kgs

After Warranty Service:

Video technical support, online support

Local Service Location:

Japan, Malaysia, Australia, Morocco, Argentina, South Korea, Chile, Colombia, Romania, South Africa, Canada, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia

Certification:

CE

Supply Ability

Supply Ability

10 Set/Sets per Day

Packaging & delivery

Packaging Details

Steel Pallet for Water Jet cnc Cutting Machine

Port

ShangHai Port

Products Description

3015 SERIES WATERJET CUTTING MACHINE 50HP

The ACCURL MAX-WJ CNC waterjet cutting series is an addition to Accurl MAX-WJ CNC waterjet cutting machine line. It provides a vigorous industrial design and rigid construction that combines precision and simplicity. The

MAX-WJ model is made to handle high production for versatile applications. The MAX-WJ waterjet cutting series provides a vigorous industrial design and rigid construction that combines precision and simplicity. The MAX-WJ model is made to handle high production for versatile applications. The MAX-WJ models come in two distinct sizes for the most common applications.

TECHNOLOGICAL ADVANTAGES

* The most versatile cutting systems on the market today, covering the full range of materials and thicknesses, even painted surfaces.

* Low cutting temperatures to prevent thermal alteration and residual tension.

* Clean cut without harmful atmospheres

* The cut surface neither cracks nor bends.

* Optimal utilization of raw material with negligible material loss

* Eliminates subsequent finishing processes.

* Ability to perform different types of cutting simultaneously

* Very strict tolerances..

FULLY ANNEALED frame

* ACCURL®steel frames undergo annealingat over 600⁰ to relieve stress.they are built to last years of heavy use withoutdistortion.

* Very stiff and stable base frame

* Dual synchronized twin servo motor drive system.

* Stress points analysis

* Usage of high-tech boring machines for extreme precision parts.

CAST ALUMINIUM GANTRY

ACCURL®s high tech Mn-steel crossbeam allows better rigidity at 50% of the weight of traditional iron gantries, allowing higher acceleration with reduced inertia.this creates less wear and tear on the machine.

YASKAWA SERVO MOTORS & DRIVES

* The Smartline is equipped with cutting edge Germany designed

* YASKAWA servo motors and drives from Japan.

* High-speed EtherCAT communication

* Highly dynamic behaviour

* Brushless three-phase motors

* Flexible motor type selection

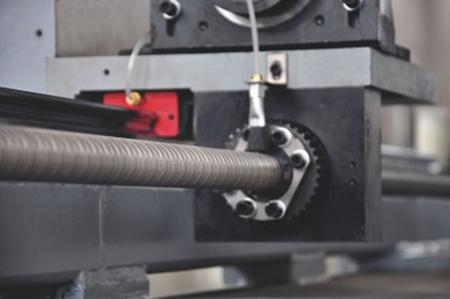

TRANSMISSION SYSTEM

* ACCURL® Waterjet are provided are equipped with constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning.

* X ,Y-Axis with HIWIN linear guide and Ball Screw.

* Less noise, greater durability and greater precision.

* Unprecedented positioning repeatability of ±0.05 (optional ±0.01).

HIGH PRESSURE PUMP

The high pressure is generated in the intensifier of the pump, actuated by an oil pump inside, and also the low water supply system. The latest generation of pumps offers the most advanced water jet technology with working pressures Up to 4200 bar. The design with a single intensifier, which generates up to 4200 bar, reduces maintenance costs and offers a quieter operation and fewer spare parts.

verified

verified