Products Description

Application fields:

* Simultaneous line boring of several holes distanced from each other;

* Restoration of seats for bearing races of gearboxes, machine beds and other housings;

* Repair of worn straight holes of road-building, quarry, mine, municipal engineering vehicles and equipment;

* Repair of worn straight holes of rolling mills and conveyors used at the heavy and metallurgical industry enterprises;

* Repair of worn straight holes of equipment used in the production, processing and transportation of raw hydrocarbons (oil, gas

and their fractions);

* Repair of units of hydraulic structures (units of sluices, drawbridges, etc.)

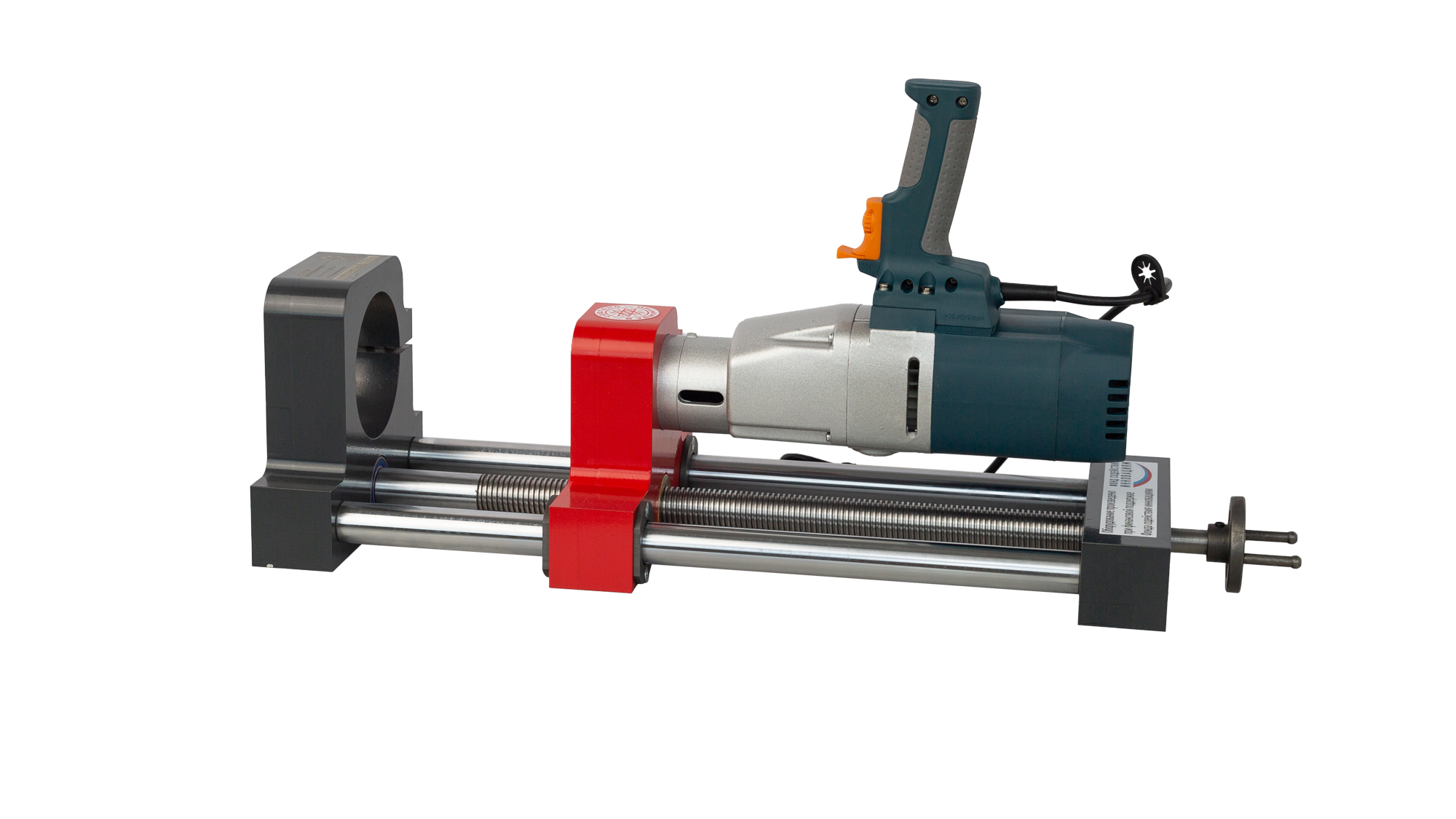

List of equipment:

* Boring bar (Ø30mm, L=1200mm) – 1 piece

* Boring cutter (D=12mm) – 1 piece

* Adapter for increasing cutter overhang (D=75mm) – 1 piece

* Adapter for increasing cutter overhang (D=120mm) – 1 piece

* Reduction sleeve (tapered) – 1 piece

* Main support – 1 piece

* End support – 1 piece

* Carbide blade – 10 pieces

* Alignment kit – 1 set

* Technical datasheet – 1piece

* Box for transportation and storage – 1 piece

When choosing machines manufactured by our company, be sure that:

* we will send you a ready-to-work machine in a complete configuration with a full set of plates and cutters

* we will modify the machine according to your needs and demands within a short time frame (up to 3 days) * we will send the machine in a timely manner as all our equipment is available from the warehouse * we will offer you the opportunity to choose any payment methods of your convenience. * the machine comes with one-year warranty and post-warranty maintenance * we will provide you with free training evidenced by the certificate * we will consult you for free within the entire period of cooperation Application fields of the portable boring machine “Pioneer”: * simultaneous coaxial boring of several holes spaced from each other at a certain distance; * restoration of seats for gearbox bearing cages, bedplates and other housings; * repairing of worn out straight holes of road-building equipment, quarry machinery, mining vehicles, utility machinery and equipment; * repairing of worn out straight holes of rolling mills and conveyors at the enterprises of heavy and metallurgical industry; * repairing of worn out straight holes of equipment used for extraction, processing and transportation of raw hydrocarbons (oil, gas and their fractions); * repairing of units of hydraulic engineering structures (units of canal locks, drawbridges, etc.). It is possible to retool the machine “Pioneer” into the bore welding complex “Pioneer РНК” *Installation of the boring bar of any size is available at option.

about Us

The Sarmat company was founded in 2009 in Izhevsk, Russia. For the first time the business area of our company was selling tools for metalworking, and then we got busy on supplying equipment for metalworking enterprises and started our own manufacturing site for mechanical tooling.

Since 2016, the main activity of the company has been the manufacturing the portable boring and overlay welding machines for the repairing of worn-out holes in special-purpose equipment and vehicles.

Portable machine tools manufactured by the Sarmat company are used in many areas, from farming industry and road-building machinery to marine and inland water transport. Their use allows to save time and money on equipment overhaul and repairs.

The equipment is manufactured by means of high-precision computer numerical controlled machines and undergoes pre-delivery inspection at our own manufacturing site with the area of about 500 sq. m.

Machines manufactured by the Sarmat company are delivered throughout Russia and neighboring countries.

In 2020, we developed and patented a mobile application for wireless control of machines through a pad or smartphone in a real time mode using Bluetooth and Wi-Fi technologies.

The company employs about 30 people on a regular basis. We are proud of design engineering department. Every single product engineer in our company has 2 patents for invention.

In addition to the manufacturing the machine tools, we provide services for the repairing of worn out holes and metalworking on the computer numerical controlled machines. In 2017 we purchased tool-grinding and machine optical profile-grinding machines and developed a new business area – qualified tool grinding.

Delivery Services

verified

verified