Min quantity:5units

Quantity:100units

Overview

Essential details

Type:

Capping Machine

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory

Showroom Location:

None

Video outgoing-inspection:

Provided

Machinery Test Report:

Not Available

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

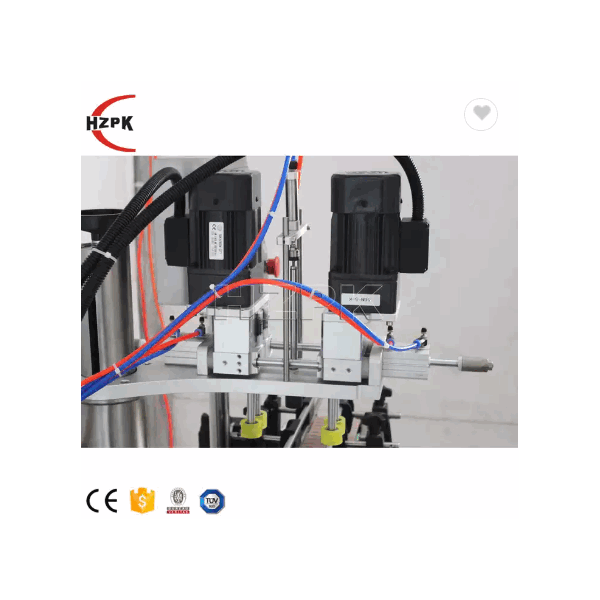

Core Components:

PLC, Motor

Condition:

New

Application:

Food, Beverage, Commodity, Chemical

Driven Type:

Electric

Automatic Grade:

Automatic

Voltage:

AC220 (110V Customizable)

Packaging Type:

Cartons

Packaging Material:

Wood

Place of Origin:

Zhejiang, China

Brand Name:

HZPK

Dimension(L*W*H):

2000*1400*1400mm

Weight:

300 KG

Warranty:

1 Year

Key Selling Points:

Automatic

Capping speed:

20-25 bots/min

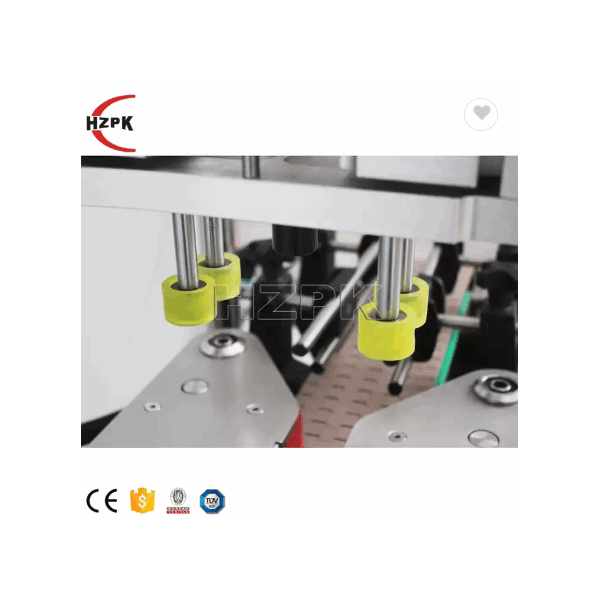

Cpa type:

Round cap, spray bottle cap, duckbill cap

Cap diameter:

25-50mm

Bottle height:

50-300mm

Bottle Diameter:

35-110mm

After-sales Service Provided:

Free spare parts, online support, Video technical support

Supply Ability

Supply Ability

3 Unit/Units per Month

Packaging & delivery

Packaging Details

Our products are packed in boxs. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxs are damaged or other situations happen, please contact us in time.

Port

Ningbp

Lead time:

Quantity(units) 1 - 1 2 - 3 4 - 5 >5 Lead time (days) 25 30 40 To be negotiated

Why Choose Us

1. More than 10 years manufacture in packing machine

2. 11 years alibaba supplier

3. 100% QC inspection before shipment

4. 12 months warranty

5. Product Certificated by CE

Product Description

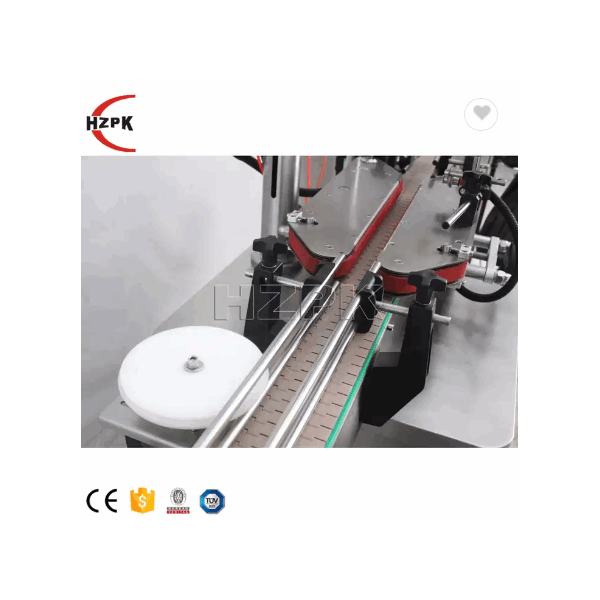

Introduction:Linear duckbill Capping machine suitable for different size of caps and bottles, screw power and rotation speed of screw capping machine is adjustable. It is widely apply to pharmaceutical, chemical, food, beverage, grease and pesticide industry.Features:1.With features like ease of operation, highly productive and competitive price etc. 2.This machine can be operated alone or coupled with filling machine, make the formation of filling line possible.