Min quantity:3sets

Quantity:50sets

Overview

Essential details

Plate Type:

Screen Printer

Applicable Industries:

Manufacturing Plant, Retail, Printing Shops, Other

Condition:

New

Place of Origin:

Guangdong, China

Brand Name:

LC

Usage:

Tube Printer

Automatic Grade:

Semi-automatic

Color & Page:

Multicolor

Voltage:

220V/ 50HZ

Dimensions(L*W*H):

98*88*139cm

Weight:

270 KG

Certification:

CE

Warranty:

1 Year

After-sales Service Provided:

online support, Video technical support, Engineers available to service machinery overseas

Key Selling Points:

High Productivity

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Bearing, Motor, Pump, Gear, PLC, Other, Pressure vessel, Engine, Gearbox

Max screen printing diameter:

180mm

max screen printing area:

300*360mm

max screen printing speed:

1500pcs/h

power:

50w

for products:

cylinder

standard:

CE approved

(Round)Max printing arc length:

L: 370mm

After Warranty Service:

Video technical support

Marketing Type:

Ordinary Product

Supply Ability

Supply Ability

60 Set/Sets per Month screen printer

Packaging & delivery

Packaging Details

plywood case/as required

Port

Yantian,Shenzhen, China.

Picture Example:

Lead time:

Quantity(sets) 1 - 20 >20 Lead time (days) 25 To be negotiated

VR

2022 New PLC Servo and sensor system Cylindrical screen printing machine With LED UV Dryer For cosmetic cream bottle jar printing

Product Description

Specifications

1.When the product is printed, it is moved to the LED lamp for drying and curing, which greatly reduces the damage to the screen frame

2.Full touch screen man-machine dialogue control mode, simple operation and safe for workers.

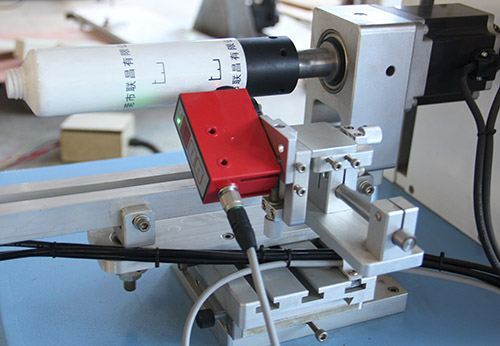

3.The signal is transmitted by German sensor and three Swiss ABB servo motors are controlled. It is suitable for multi-color overprinting of bottles without registration points for various special-shaped products

4. This is a high precision and high efficiency surface screen printing machine, left and right, rotation, shuttle full servo control, up and down using three-phase frequency conversion motor control,printing balance vibration is small, high precision, stable operation, multi-color overprinting accurate; Adopting double column structure, PLC system, running smoothly at high speed.

5. The left and right movements of the printing head are driven by linear guide rails. Double guide column left and right mesh clamping arm, at the same time install plate distance adjustment device,printing accuracy: ± 0.03mm, running speed can reach 1800 times per hour.

6.Emergency stop automatic rise alarm shutdown device,more humanized, higher safety factor.

Details Images

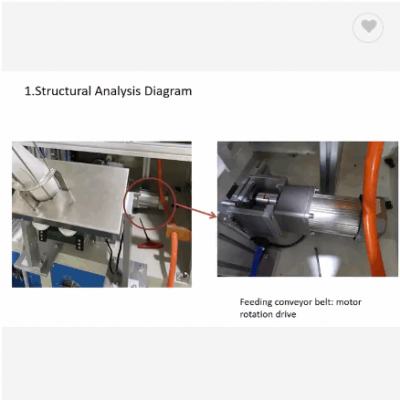

servo and sensor system

servo system for color registration,High precision

Microcomputer control screen

Console,Operating machine systems, switches

Ink return knife/rubber squeegee

Freely adjustable angle

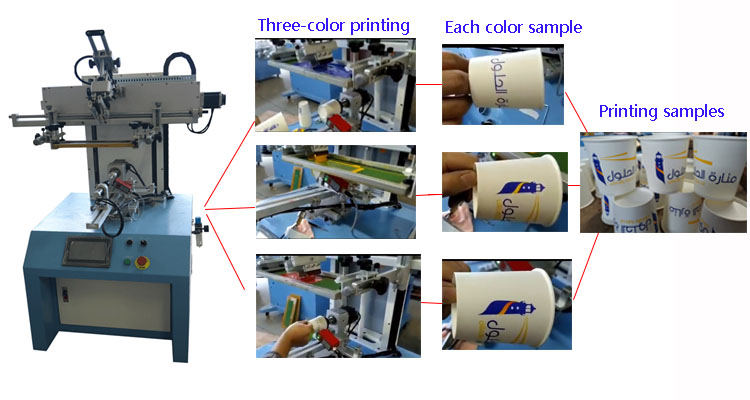

Application For Semi-automatic Screen Printing Machine For Paper Cup

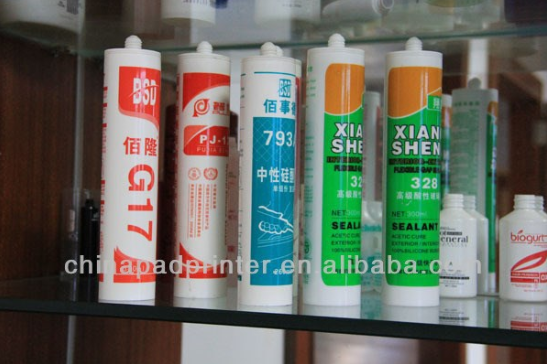

It suitable for precise printing substrates in Cylindrical, forms whic h with smooth curve surface and made of various materials such as metal, plastic, ceramic, glass, wood etc.Printing objects such as lipstick, cosmetic bottles, scour bottles, drink bottles, pots, oil-filter shell etc.

Main Features For Semi-automatic Screen Printing Machine For Paper Cup

1. Round printing function (taper section)

2. Automaticoil scrabbing, oil return and lifting table

3. Adujustability of routs and speeds

4. Self-poise scraper to balance printing pressure

5. Adjustable table (fluctuation & round) and netting easel (fluctuation & both sides)

6. High precision and easy & quick adjustability

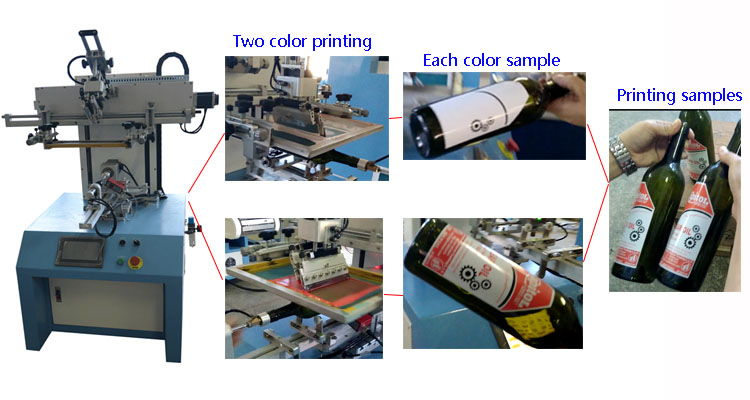

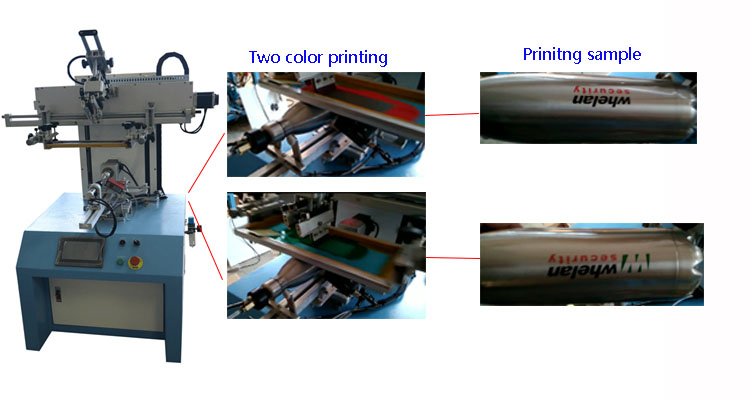

Printing Samples

Printing process of multicolor paper cup

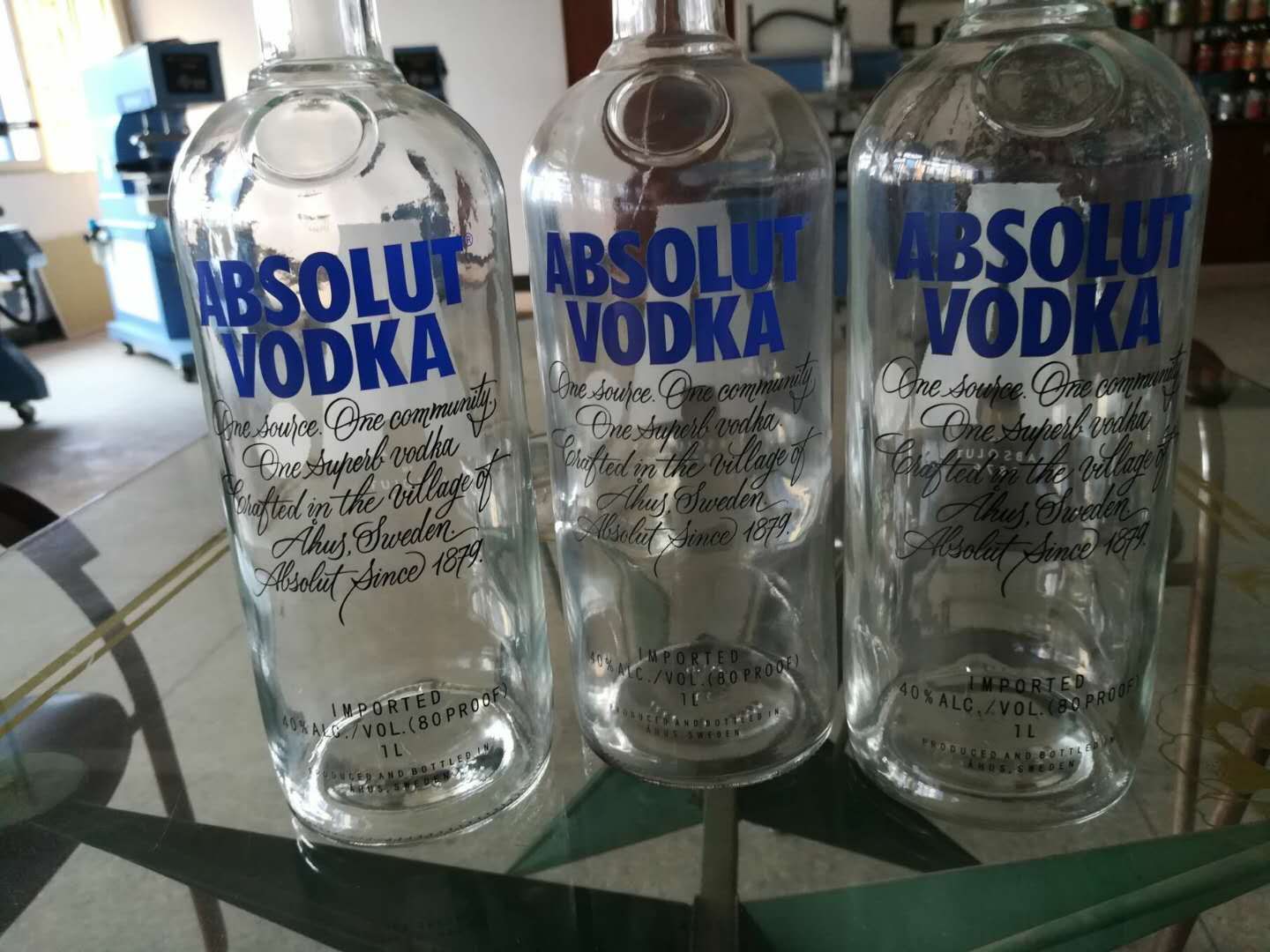

Printing process of 2 colors wine bottles

Printing process of Thermos

More pictures and video of the machine , please contant with us.It can print various materials bottles, cups, tubes, etc.

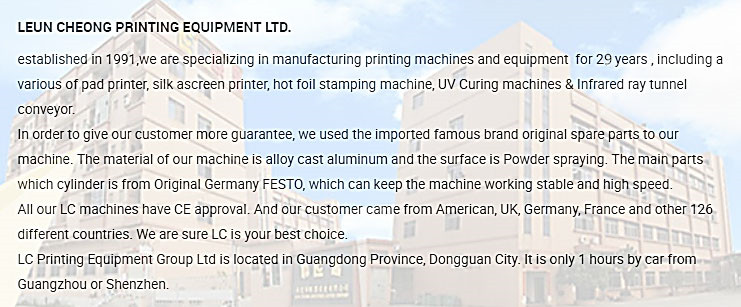

Company Information

Our company was founded in 1991 and has 29 years of production experience. At the same time, we are a 12-year Alibaba store,producing machines all over the world.

Foreign Cooperative Partners

Photo of Factory

Packaging & Shipping

★ Packing & Delivery

1. Packing: Plywood Case for Each Machine

2. Payment terms: T/T (50% deposit to start the production, 50% paid before delivery)

3. Delivery date:3-15 business days after received the payment.

4. Delivery means: By sea from ShenZhen Port