Min quantity:1Piece

Quantity:999Piece

Deliver:In 7 days

Overview

Essential details

Place of Origin:

China

Condition:

New

Weight (KG):

80

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Ordinary Product

Warranty of core components:

2 years

Core Components:

PLC

Warranty:

2 years

Applicable Industries:

Other

Showroom Location:

None

Name:

Industrial Robot Arm

Type:

Six-axis Vertical Multi-joint

Function:

Picking Lifting Handing Placing Positiong

Axis:

6 Axis Robot

Technics:

System Assembly

Payload:

6KG 10KG 20KG 50KG

After-sales Service Provided:

Engineers available to service machinery overseas

After Warranty Service:

online support

Advantage:

Save Human Resource

Packaging & delivery

Packaging Details

1.Standard wooden cases with sponge filled inside for packing protection

2. Customized Packing as per Customer's requirement.

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 15 To be negotiated

Video Description

Professional 6 axis welding robot arm length 1400mm TIG MIG robotic welding system on sale laser welding machine with robot arm

Product Description

Product Introduction:

MR Series welding robots with compact, small size and light weight and good welding precision and reliability, are dedicated arc welding robots which has the welding to achieve a stable , highly accurate welding path , shorten cycle welding , pipe fittings and cables extend life. Meanwhile MR Series welding robots can do the welding for a flexible work in a small space, you can easily select the ground installation, mounting, flip, etc.

Features:

1. Small size

2. Light weight

3. High running speed

4. High position repeat accuracy

5. Good welding reliability

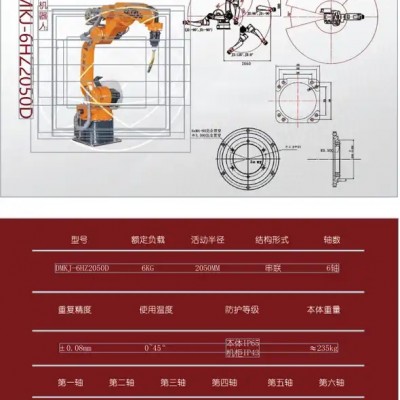

Principal Data

Model | MR1400 | |

Payload | 6 KGS | |

Max Working Radius | 1405 mm | |

Arm Length | 2391 mm | |

Number of Axis | 6 | |

Max speed | Axis1 | 150 °/S |

Axis2 | 150 °/S | |

Axis3 | 160 °/S | |

Axis4 | 360 °/S | |

Axis5 | 320 °/S | |

Axis6 | 360 °/S | |

Max Operation Area | Axis1 | ±165° |

Axis2 | +155° ~ -90° | |

Axis3 | +70° ~ -200° | |

Axis4 | ±170° | |

Axis5 | ±120° | |

Axis6 | ±360° | |

Max moment Allowable Torque | Axis5 | 54 NM |

Axis6 | 23 NM | |

Weight | 140kg | |

Position Repeatability | 0.05mm | |

Working temperature | 0-45 ℃ | |

MR1400 Robotic Arm Standard Configuration List | |||

Control System | SMR1000 Controller + STEP Series Servo Driver | ||

Item No. | MR1400 | ||

Servo Motor Brand | TAMAGAWA MOTOR | ||

Length of power line | 5M | ||

Length of encoder lines | 5M | ||

Length of power supply line | 5M | ||

The teaching machine brand | Keba/SRTP1000 | ||

Length of teaching machine line | 5M | ||

Communication | Category | Name | Specifications |

Bus | EtherCAT bus | 1 piece | |

CANopen | 1 piece | ||

RS232/RS485 | 1 piece | ||

IO | digital input DI (Weidmuller) | 1 piece(16 road) | |

digital output DO (Weidmuller) | 1 piece(16 road) | ||

Others | Ethernet Standard Ethernet interface | 1 piece | |

Accessories | CD(Software, Project, electronic user manual) | ||

Remark | |||

Application----Arc welding

l Stabilize and improve welding quality and ensure its homogeneity

l Improve productivity, a day to 24 hours of continuous production

l Improving labor conditions, long-term work in hazardous environments

l Reduce operational technology requirements for workers

l Shorten product modifications and updating cycle, reduce the corresponding investment in equipment

l Can achieve mass production welding automation

l Save floor space