Min quantity:1Piece

Quantity:999Piece

Deliver:In 7 days

Overview

Essential details

Place of Origin:

Hubei, China

Brand Name:

DMJK

Condition:

New

Weight (KG):

225

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

2 years

Core Components:

PLC, Gearbox, Gear

Warranty:

2 years

Applicable Industries:

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Food Shop, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Showroom Location:

Argentina

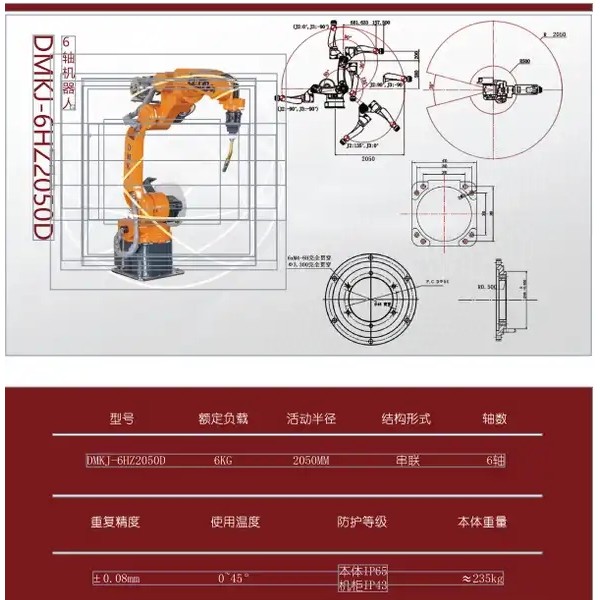

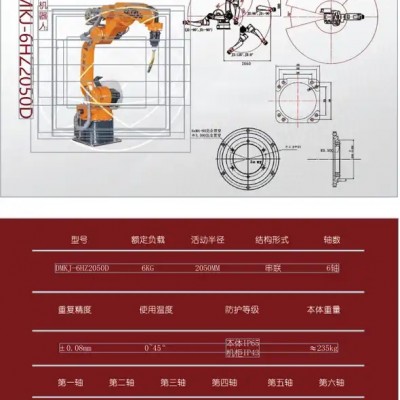

Axis:

6 axis

Payload:

50

Armlength:

819mm

Control:

TCP/IP,Modbus TCP,Modbus RTU

Certificate:

CE

Service:

Free training, online service or overseas serivice

Function:

glue, painting, welding, cutting, palletizing

Keyword:

Smart Robot

Advantage:

collaborate

Weight:

225Kg

Supply Ability

Supply Ability

200 Unit/Units per Year OEM is OK

Packaging & delivery

Packaging Details

Wooden package

Port

shanghai or any

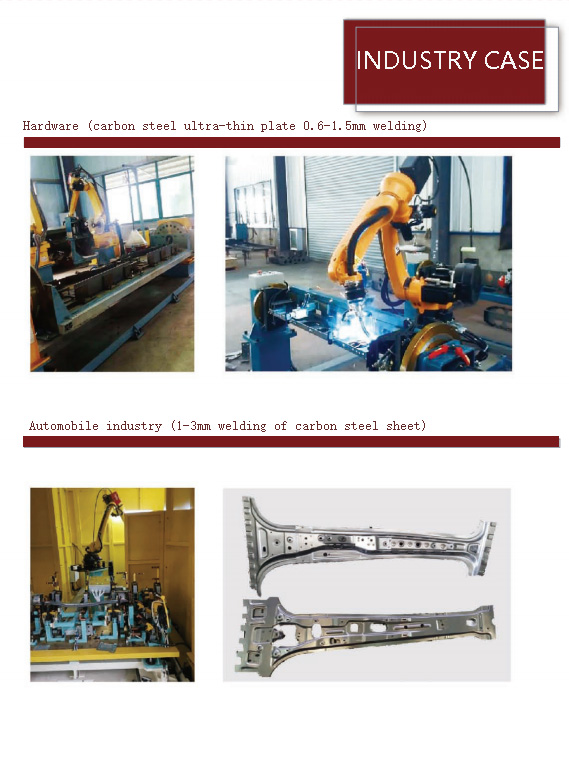

Picture Example:

Lead time:

Quantity(sets) 1 - 1 2 - 2 >2 Lead time (days) 7 10 To be negotiated

Video Description

High precision Industrial Robotic Arm KiKA 6 Axis Robot for painting / transporting / placing / arc welding / cutting/ Automatic System

Features:

1. based on carbon steel CO2 HSP short arc pulse telling welding function development special welding machine

2. Ultra-low spatter welding developed for thin plates, dedicated to special machines, and highly targeted for application scenarios 3. It can achieve high-efficiency and high-quality welding of 0.6MM thin plates

4. Through ultra-high-speed sampling of welding current and voltage, high-precision waveform control is realized to achieve high-quality welding

5.CO2 welding can achieve the effect of conventional MAG welding, reducing customer gas usage costs and manual grinding costs

6. Greatly improve the arc stability from the second current region to the high current region

7. Low spatter control can be achieved during high-speed welding

8. During HSP high-speed welding, the arc length is short, the directivity is strong, and the walking speed is greatly improved

9. Welding speed increased by more than 50%

10. During HSP high-speed welding, the welding heat input is low, which can realize ultra-low spatter welding

11. Splash reduction by 90%

Equipment list:

| Product name | Specification | Quantity | Unit | Remark |

| DMKJ-6HZ1500DA | DMKJ-6HZ1500DA | 1 | Set | |

| Robot Arm | DMKJ-6HZ1500D | 1 | Set | |

| Robot Controller | DMKJ-KG01A | 1 | Set | |

| Teaching Box | DMKJ-SJ 01A | 1 | Set | |

| Operating Box(5m) | DMKJ-CZH01A | 2 | Sets | |

| Robot power signal line | 1 | pc | 6 Axis serve motor | |

| Robot welding machine communication line | 10 cores/5 meters | 1 | pc | Control cabinet/welding machine communication |

| Control line(10cores*meter) | 10 cores/3 meters | 1 | pc | Robot to Control Cabinet/Welder |

| Robot supporting cable | Positive wire | 1 | pc | Robot to wire feeder / welder to workpiece |

| Robot supporting cable | Negative wire | 1 | pc | |

| Robot electric control cabinet power cord | YZ3*2.5/5 Meters | 1 | pc | |

| Welding power source | CPM-360 | 1 | pc | |

| 350 Air cooled torch | DMNK-350 | 1 | pc | |

| Bumper | 1 | pc | ||

| Torch cable | 0.85m | 1 | pc | |

| Wire feeding mechanism | DMSS-0D | 1 | Set | |

| Wire Feeder Stand/Wire Feeder Box | 1 | pc | ||

| Wire Reel Holder | 1 | pc | ||

| (wire feed/air feed) control cable | 1 | pc | Body to wire feeder | |

| Solenoid valve and connector | 1 | pc | ||

| Rear fast wire feeding tube (2 meters) | 1 | pc |