Min quantity:1Piece

Deliver:In 7 days

Overview

Essential details

Applicable Industries:

Printing Shops

Showroom Location:

Uzbekistan

Video outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Hot Product 2019

Warranty of core components:

6 Months

Core Components:

PLC, Engine

Condition:

Used

Type:

Computer to Plate

Automatic Grade:

Automatic

Place of Origin:

Zhejiang, China

Brand Name:

Hans Gronhi

Year:

2013

Voltage:

220V/50HZ

Dimension(L*W*H):

050x950mm(WxDxH)

Weight:

200 KG

Warranty:

6 Months

Key Selling Points:

Automatic

Supply Ability

Supply Ability

10 Set/Sets per Month

Packaging & delivery

Packaging Details

wooden box

Port

Qingdao/Tianjin

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 12 To be negotiated

Video Description

Product Description

Product Application

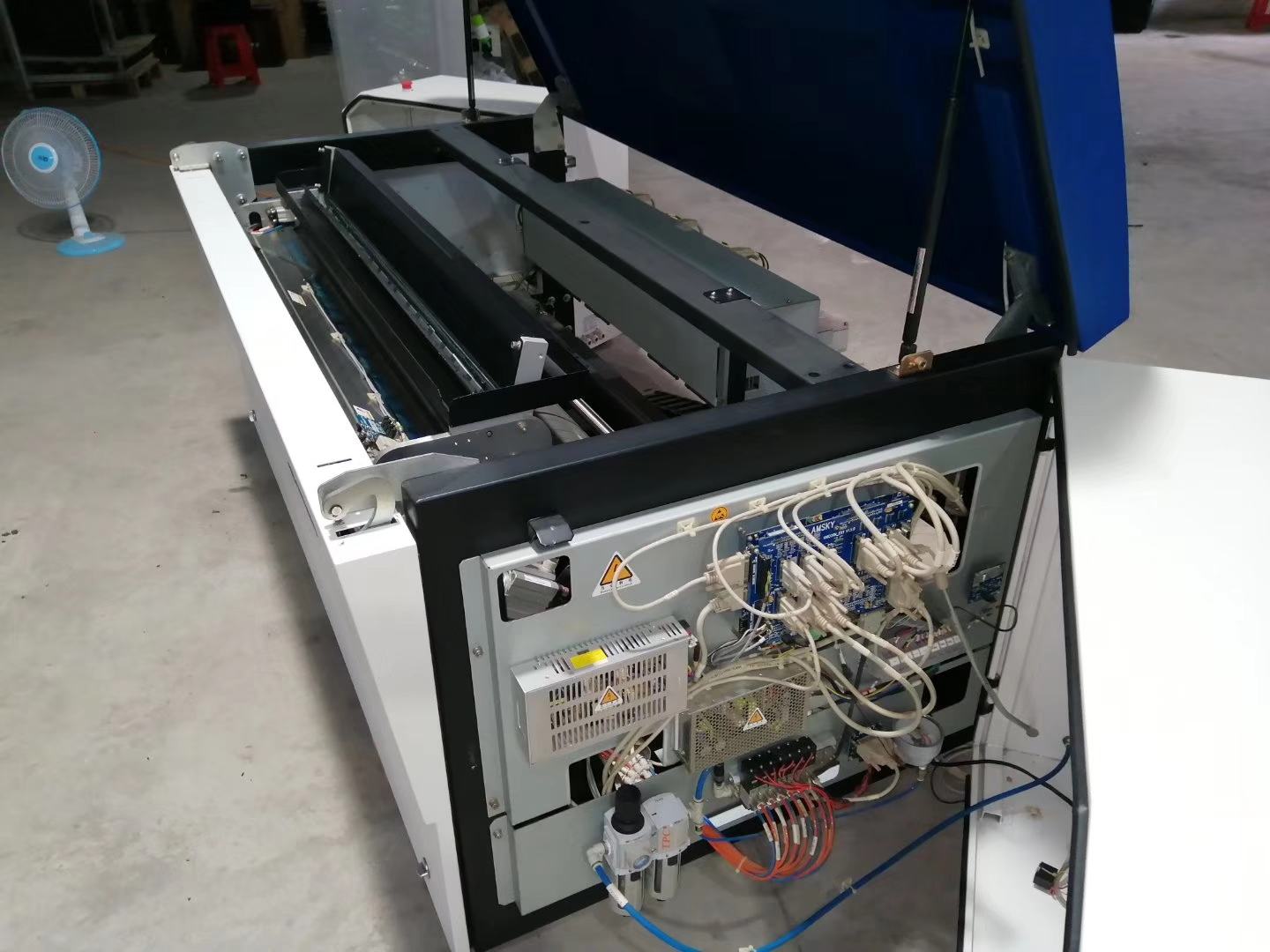

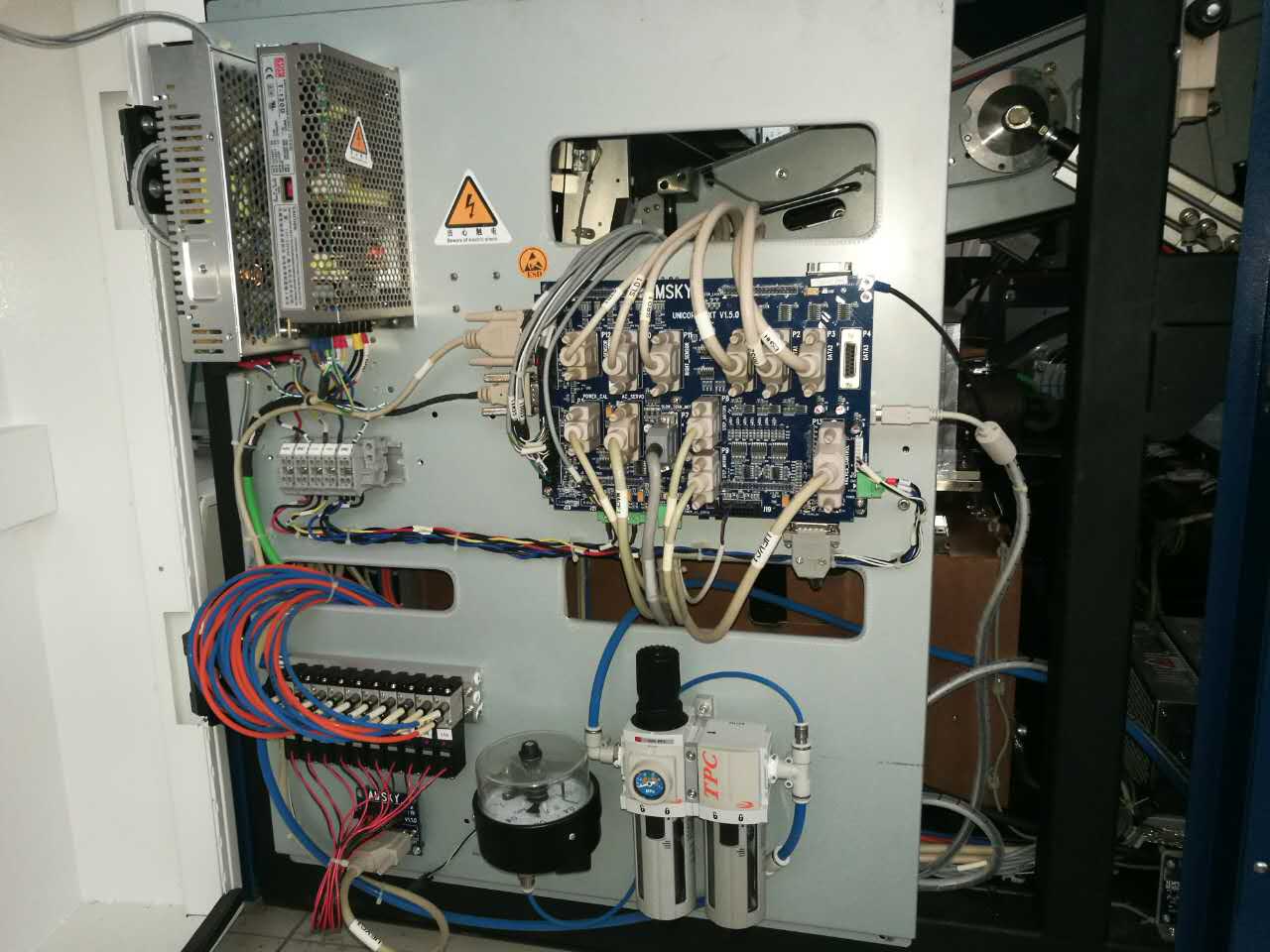

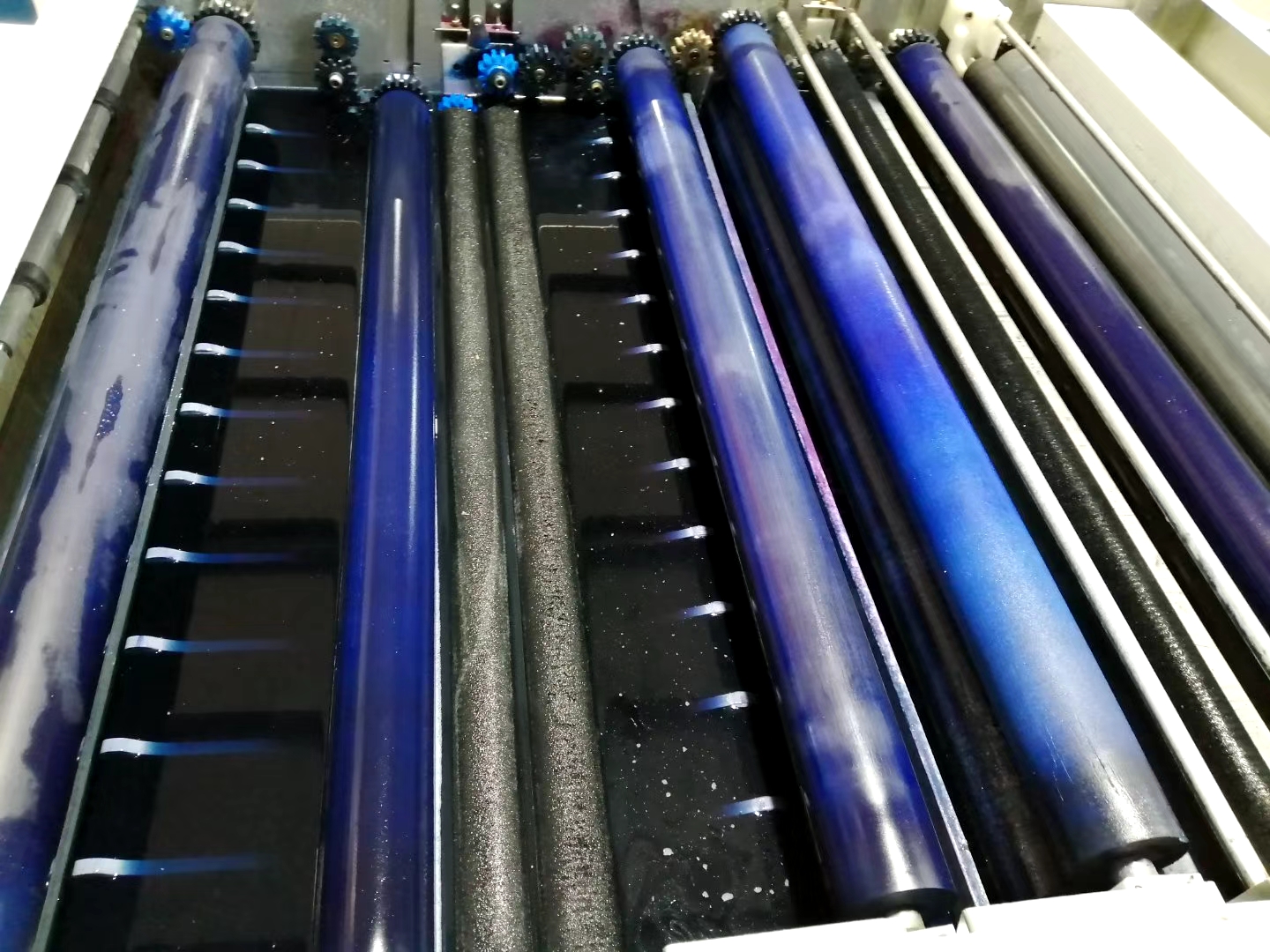

USED pre press Amsky UV CTP Computer to Plate.CTP.Thermal CTP,UV CTP Plate maker CTCP machine

Main Features

USED Computer to plate CTP

1) The process software is supporting PS and PDF file which is generated by kinds of common use plate maker software like In design and Word and also other kinds of Image format file

2) RIP color separation make all kinds of image, diagram and characters during the computer plate making into the recordable bitmap information from the maker. This information can be made as CMYK with different precision which have the screening angle

3)The makeup process function make the image and the characters finish the makeup on the page after the RIP and also the folding hand process function can demarcate the page number and sequence according to the size of the paper automatically.So its convenience totally change the working pattern of the traditional makeup performance, to make the operation easy, convenient and fast so that the work efficiency is improved.

4) When the CIP3 is under the process of the ink amount preset, the RIP work on the page,in the mean time of the makeup performance, the layout printing ink information will be interpreted and keep in the PPF files and then transferred into the press by internet. The press controlled identify and proceed the ink preset automatically,so the rationality and accuracy of the ink area distribution of the press is enhanced greatly