Min quantity:1Piece

Deliver:In 7 days

Overview

Essential details

Type:

Offset Printer

Applicable Industries:

Printing Shops, Advertising Company

Showroom Location:

Uzbekistan

Condition:

Used

Plate Type:

Flatbed Printer

Place of Origin:

Japan

Brand Name:

ryobi

Usage:

Paper Printer, Label Printer, Card Printer, Bill Printer

Automatic Grade:

Automatic

Color & Page:

Multicolor

Voltage:

380v

Year:

2016

Make:

komori

Dimensions(L*W*H):

4330x1820x1720mm

Weight:

9000 KG

Warranty:

1 Year

Key Selling Points:

Automatic

Marketing Type:

Ordinary Product

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

6 Months

Core Components:

Bearing, Motor, PLC

Application:

Brochures posters, magazines ,paper card

PLATE SIZE:

510x410x0.15mm

Printing speed:

12000sheet per hour

Color:

4-5 colors

Min sheet size:

520x360mm

Material:

28-450gsm

plate laoding:

automatic

Supply Ability

Supply Ability

10 Set/Sets per Month

Packaging & delivery

Packaging Details

Seaworthy packaging 20 or 40ft container

Port

Qingdao

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 15 To be negotiated

Video Description

Product Overview

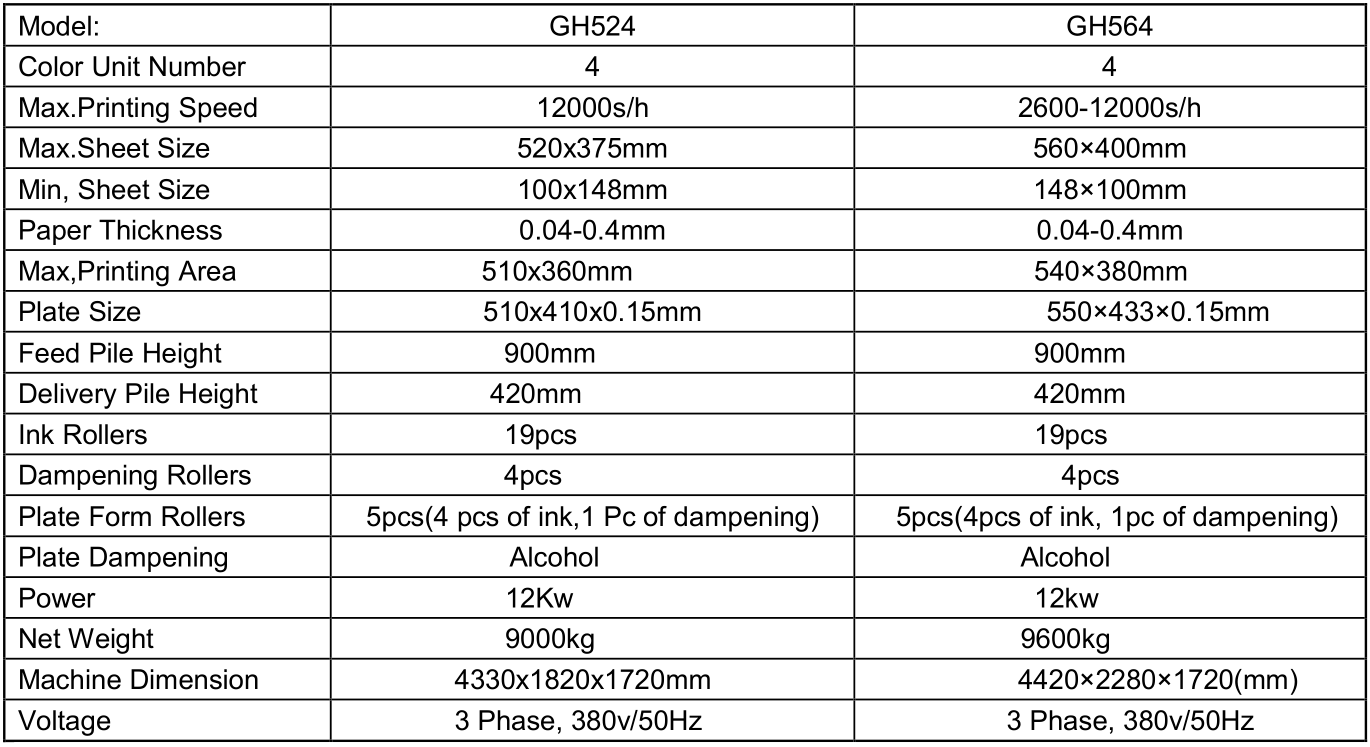

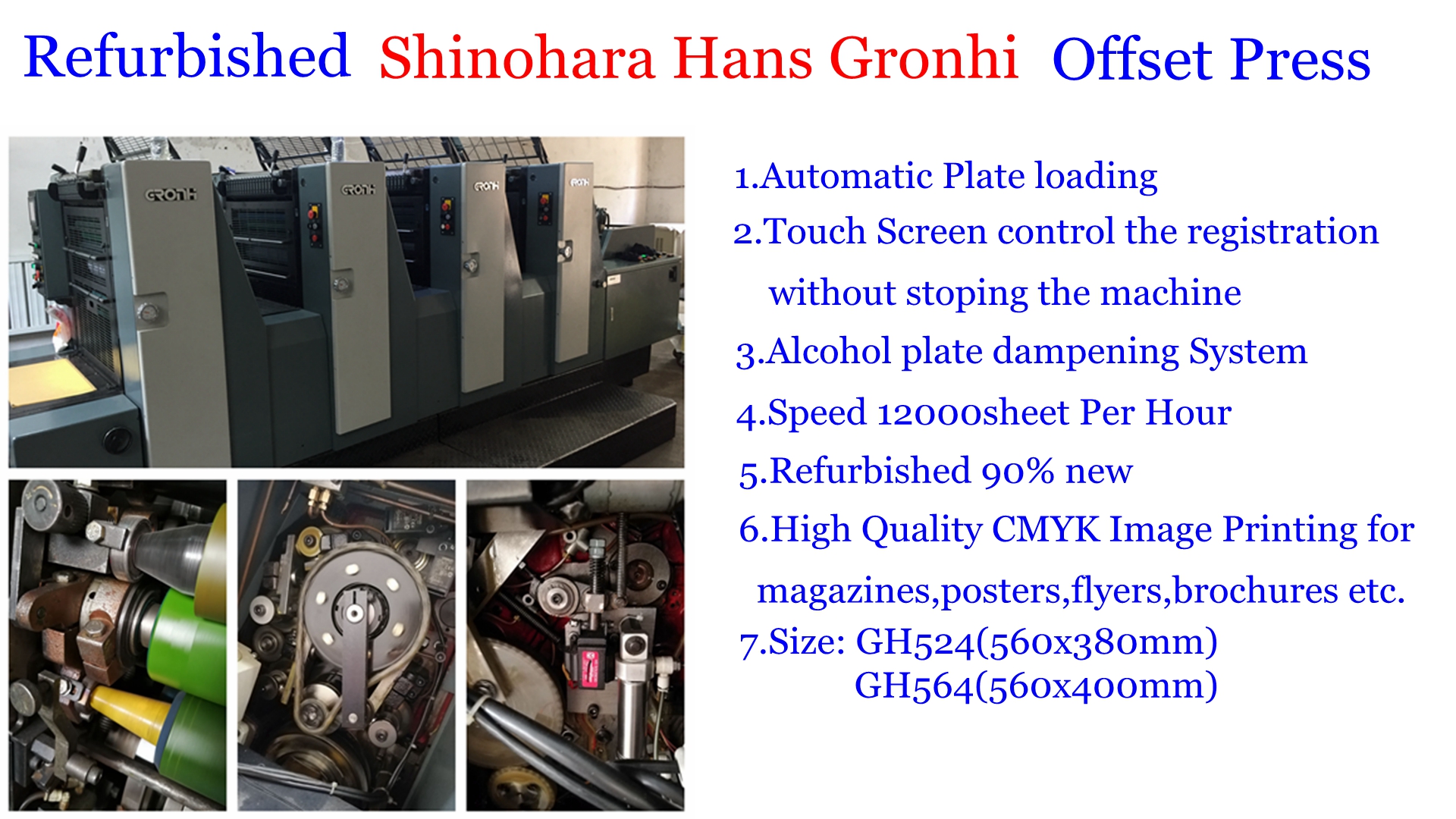

Ryobi Komori akiyama shinohara HANS GRonHI AUTOMATED 52CM FOUR COLOUR PRESS REFURBISHED GH524

refurbished shinohara gronhi GH524 , the machine 90% new, Machine working speed is 12000sheet Per Hour, Auto plate laoding( 4 plate only need 2 minutes). Computerized registration, Acohol Dampening system. Super printing quality for CMYK magzines,bruchures, posters. Price is very cheap.

FEATURES AT A GLANCE

High levels of automation

Low power consumption Low cost consumables Small footprint Super fast makeread

Low cost per sheet High end commercial quality

PRODUCT SPECIFICATIONS

PRODUCT CONFIGURATION

Our Advantages

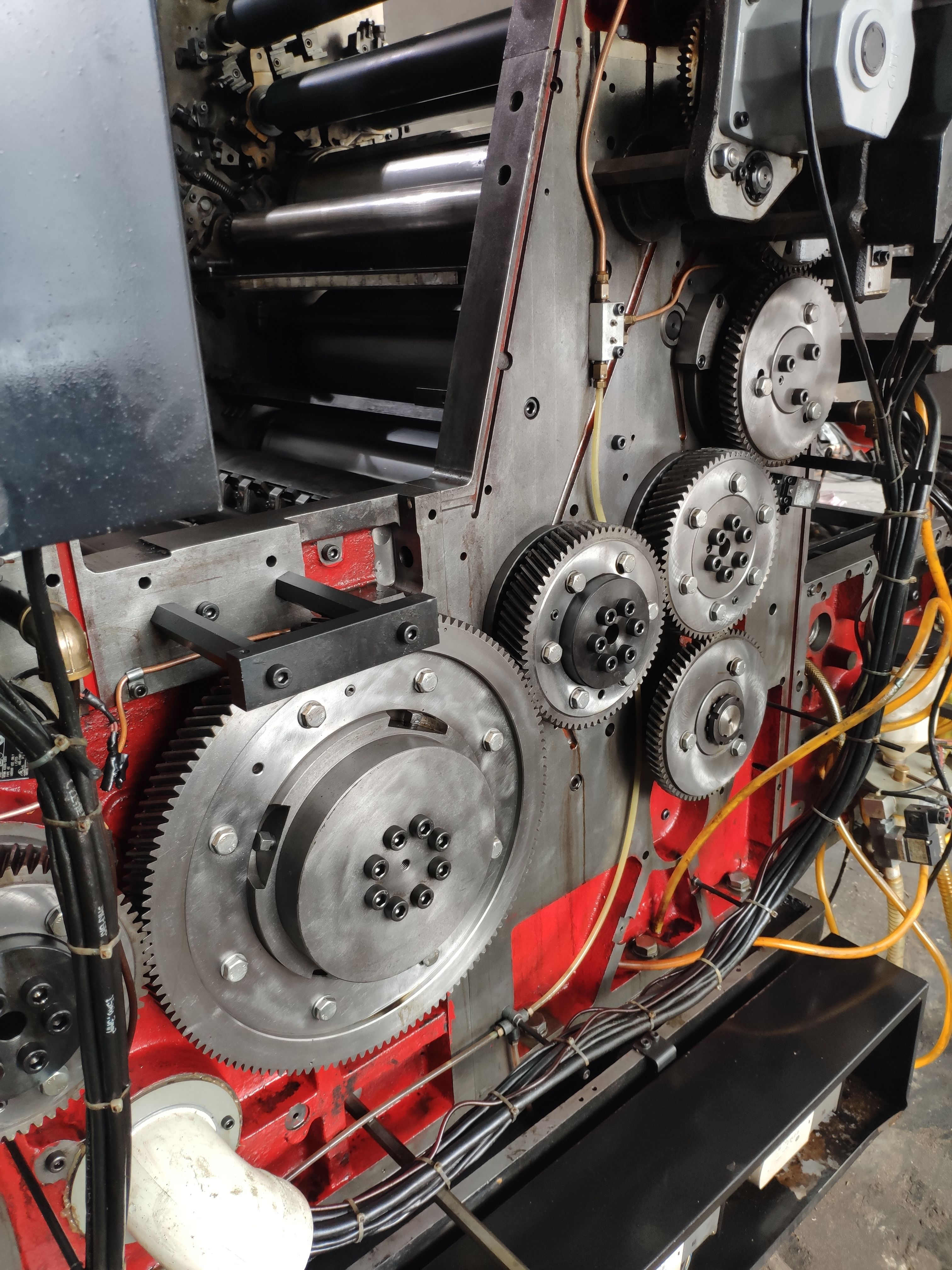

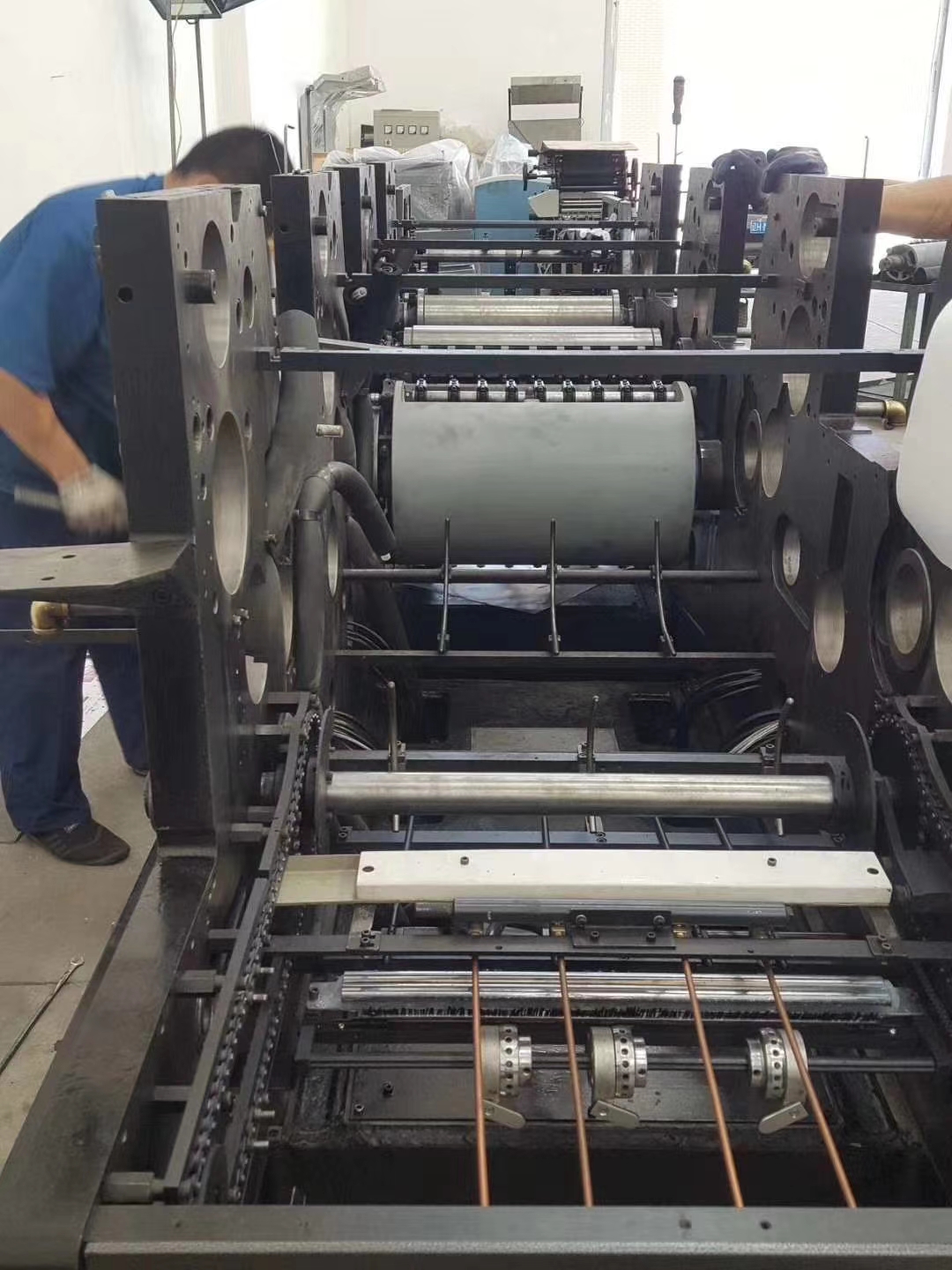

Stream feeder with suction belt feed board Mechanical and ultrasonic double sheet detection Pneumatic side lay Continuous monitoring of sheet arrival at front lays Semi automatic plate loading with pre load facility Precision laser cut segmented ink keys Continuous metered dampening system with an oscillating bridge roller and pre-damp facility Optional integrated or separated dampening during production Speed compensated damping Automated refrigeration - recirculation and dosing unit Cylinder movement-circumferential-lateral and diagonal Quick release blankets Touch screen controls Programmable pre-dampening cycle Powder spray unit with heated reservoir and vibration Three motorised suction slow down devices Sheet de-curler Air shower in delivery Central oil shower lubrication system Pneumatically controlled operation