Products Description

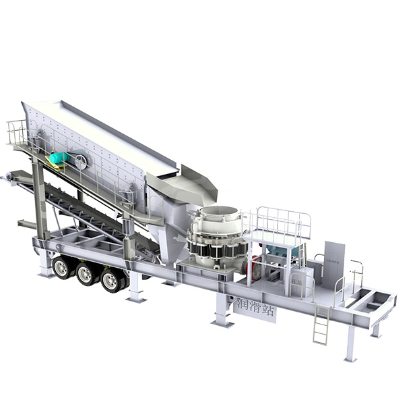

Product Application:

Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all kinds of ores and other grind-able materials.

Main Features:

1) This Ball mill machine changes the intrinsic grinding mill structure.

2) Its body and ground plank are an integral whole. So when fixing, it can be lowered on a plane surface once only.

3) Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%.

4) The intrinsic grille pattern forcing evacuation is instead by over fall pattern controlling one. This can improve the milling of the granule and the quantity dealt with is reduced by 15-20%.

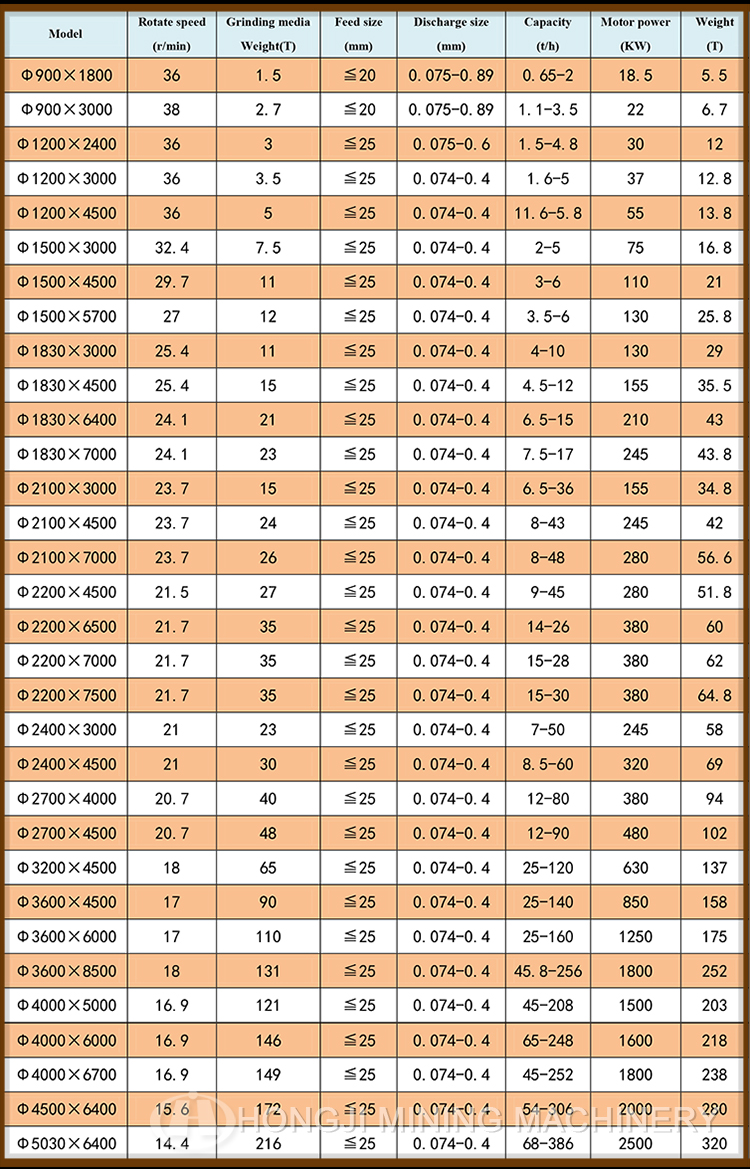

Product Paramenters

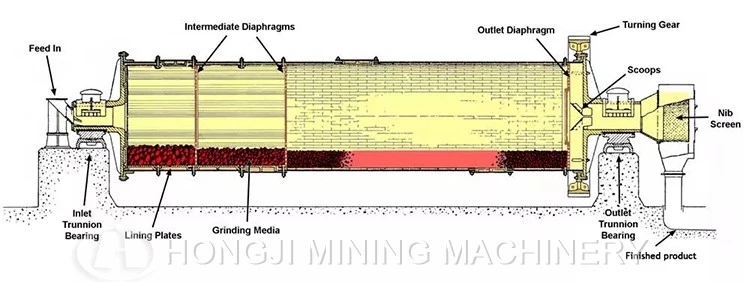

Working principle

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

Our Advantages

Packing & Delivery

Packing: Conventional Packaging suitable for long distance transportation.

Delivery: 10-30 working days after receiving the deposit of the devices.

Our Successful Case

verified

verified