Min quantity:1Piece

Quantity:999Piece

Deliver:In 3 days

Overview

Essential details

CNC or Not:

CNC

Condition:

New

Machine Type:

Punching Machine

Slide Stroke (mm):

230

Power Source:

Mechanical

Place of Origin:

Anhui, China

Brand Name:

AccurL

Voltage:

380V/220V Optional

Dimension(L*W*H):

5940*5220*2420mm

Motor Power (kW):

10.5

Model Number:

MAX-SF-30T

Weight (T):

13500

Key Selling Points:

Flexible Manufacturing

Warranty:

3 years

Applicable Industries:

Hotels, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Construction works

Showroom Location:

United Kingdom, United States, Italy, France, Germany, Brazil, Saudi Arabia, Indonesia, India, Russia, Morocco, Chile, Romania, Australia

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

2 years

Core Components:

Bearing, Pump, Motor

After-sales Service Provided:

Engineers available to service machinery overseas

Punch Force:

30 tons

Max. sheet Thickness:

6.35mm

Max Punching Diameter:

88.9mm

Servo System:

Siemens servo drive

CNC System:

Siemens Sinumerik 840D Windows XP

Main motor:

Siemens Electrical

Electrical components:

Siemens Electrical

Application:

metal Sheet Stamping

Product name:

CNC Turret Punching Machine

Supply Ability

Supply Ability

15 Set/Sets per Week

Packaging & delivery

Packaging Details

Steel Pallet for Punching Machine

Port

Shanghai port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

Video Description

Products Description

SERVO CNC TURRET PUNCH PRESS MAX SF SERIES

The new generation of ACCURL turret punch is a low energy, high efficiency turret punch with low environmental and maintenance costs. The ACCURL can be configured in 22 or 33 ton options. The ACCURL was designed with a thick turret to ensure longevity of the machine and its tools and to minimize tool deflection.ACCURL performs full punches, hovering, marking and forming operations. The SF model can be upgraded with our Ultra Package which can decrease part processing times by up to 40%.

The ACCURL comes standard with the following features:

Automatic Tool and Linear Components Lubrication System

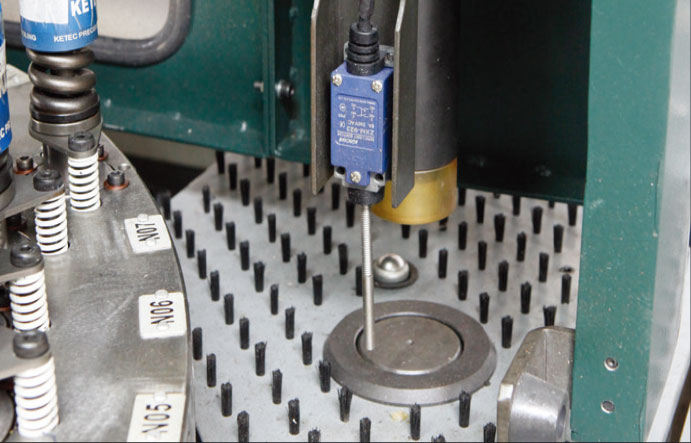

Pneumatic Ball Transfer and Brush Table for ease of loading/unloading

Vacuum Assist System for slug removal

32 Stations 2 Auto indexing stations

One Mirror-Type Safety System to guard entire work envelope

Man-Sensors on moving tables

Sheet Jam Protectors to detect warped material

Sheet-gripper sensors to detect loose material

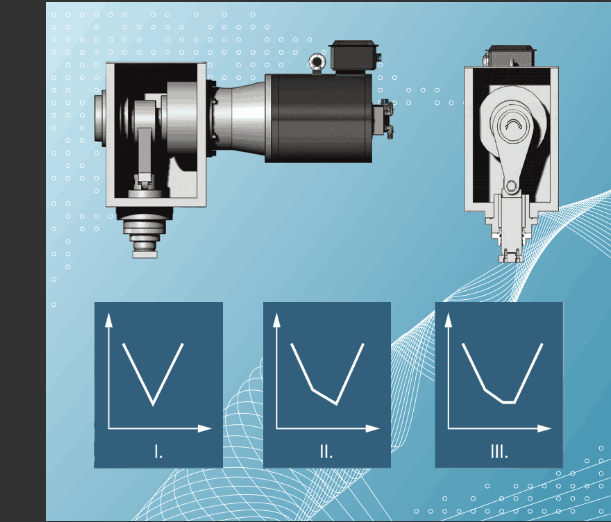

SERVO DRIVE SYSTEM

The punch servo utilizes a direct drive gearbox that supplies power and speed. This servo allows the user to steplessly adjust the punch stroke and accommodate any pressure curve requirements.

The AC punch servo motor can be programmed for various applications.

1. High speed applications.

2. Low noise applications.

3. Forming applications.

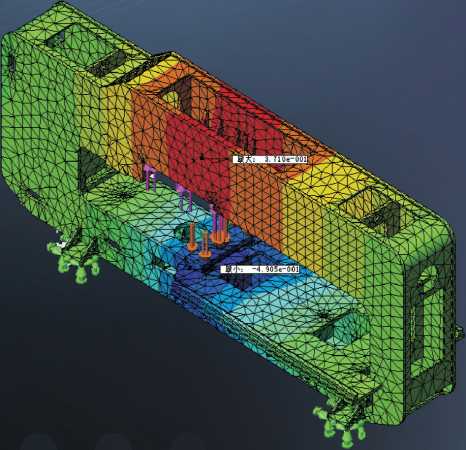

SOLID FRAM E STRUCTURE

The ACCURL turret punch utilizes an O-frame structure for rigidity and reliability throughout the life cycle of the machine.

QUALITY ENBINEERINS

All frame configurations are field tested and engineered to last using FEA.

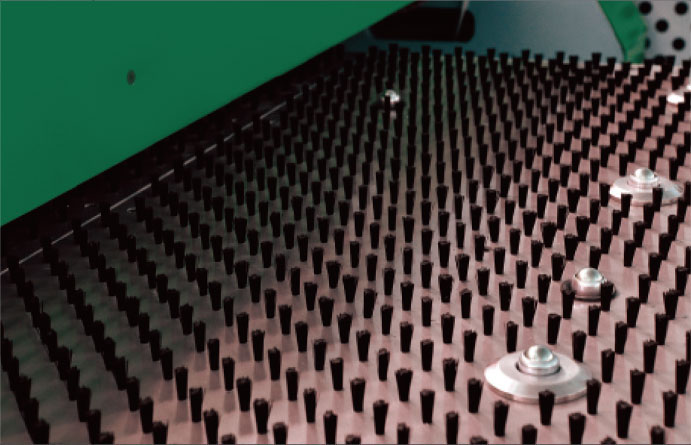

MIXED BALL AND BRUSH TABLE

The standard configuration features a mixed ball and brush table that comes with an

integrated pneumatic ball transfer table to ease loading and unloading.

SHEET JAM PROTECTORS

Sheet Jam Protectors automatically detects deformed or buckled sheets and automatically

stops the machine when triggered.

DROP CHUTE & CONVEYOR

The part Drop Chute and Conveyor options allow processing and sorting to be automated and simplified.

AUTOMATIC CLAMP POSITIONING

Automatic Clamp Positioning reduces set up time and errors, and provides machine run time flexibility and productivity.

MAXIMUM ConTROL

The ACCURL turret punch comes with a FANUC Oi-PD LCD mounted controller. The setup includes an ACCURL Operator panel and FANUC MDI panel.

The FANUC controller allows for precise and reliable machine control, as well as providing a way to monitor secondary systems and keep track of maintenance tasks.

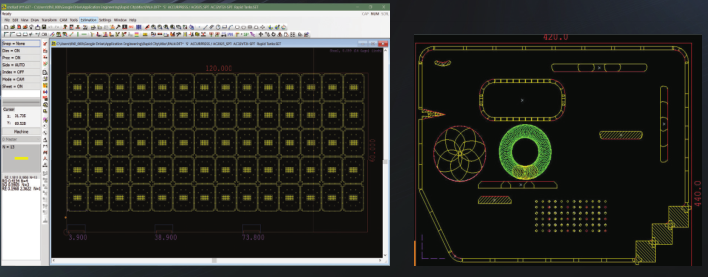

CAD/C AM NESTING SOFT WARE

The G-code for the Oi-PD controller can be generated from nesting software. The operator may nest multiple parts, maximize sheet utilization and streamline their workflow to ensure their turret punch is working in peak condition.