Min quantity:1Piece

Quantity:999Piece

Deliver:In 7 days

Overview

Essential details

Applicable Industries:

Hotels, Garment Shops, Food & Beverage Factory, Restaurant, Home Use, Food Shop, Printing Shops, Food & Beverage Shops, Advertising Company, Other

Showroom Location:

Egypt, Italy, Algeria, South Africa, Morocco

Condition:

New

Type:

Die-cutting Machine

Computerized:

Yes

Place of Origin:

China

Brand Name:

PRINTYOUNG

Voltage:

380V

Dimension(L*W*H):

4880 x 2100 x 2350 mm

Weight:

14000 kg

Warranty:

1 Year

Production Capacity:

7000 S/H

Key Selling Points:

Automatic

Max. workable width:

1080mm

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

Core Components:

Motor, Engine

PLC Brand:

OTHER

Max paper size:

1080 x 780 mm

Min paper size:

400 x 330 mm

Max cutting size:

1075 x 770 mm

Die frame inner size:

1100 x 790 mm

Cutting plate size:

1080 x 780 mm

Min gripper edge size:

7 mm

Cutting precision:

≤±0.1 mm

Max cutting pressure:

300 T

Pre-stacking height:

1550 mm

Delivery stack height:

1400 mm

Supply Ability

Supply Ability

5 Set/Sets per Year

Packaging & delivery

Port

Shanghai or Ningbo

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 60 To be negotiated

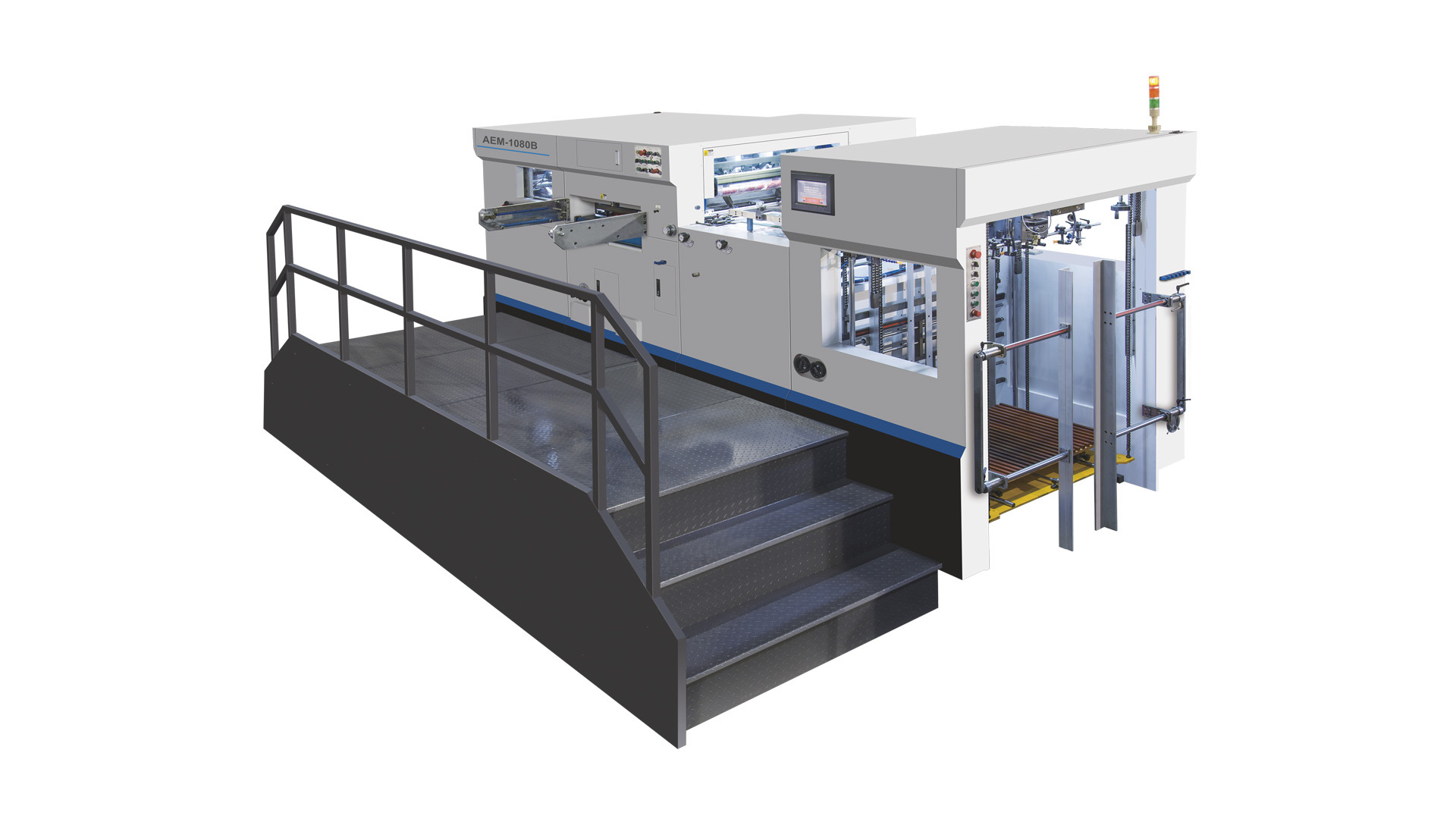

AEM-1080B Automatic Flat Bed Die Cutting Machine

Features

★ Complete design, accurate installation, high stability, high security, low noise.

★ Adopt worm, worm gear, crankshaft transmission, high cutting pressure, high durability.

★ High precision interval mechanism, high cutting precision, running steadily.

★ Adopt European feeder, suction adjustable, steadily, precise, good paper applicability.

★ Non-stop feeding, pre-stacking and delivery device can shorten the auxiliary time, improve the efficiency.

★ Automatic pressure adjust system, pressure digital display.

★ Human-friendly designed die frame and baseplate, makes installation, adjustment convenient.

★ Pneumatic die locking device, die frame fixed more steadily, accurately, time saving.

★ Front lay, side lay, feeding device fine tuning device, paper positioning more accurate,

★ Double, crooked, no-sheet optoelectronic position control, ensure the paper in the right position, reduce waste.

★ Electronic control module design, adopt imported electronic components, ensure the accuracy and reliability.

★ Touch screen man-machine interface, real-time monitor the running situation, makes machine adjustment, trouble shooting more convenient.

★ Cycling cooling oil supply system ensure the movement parts get adequately lubricated to ensure the durability.

★ Adopt fixed quantity at fixed timing oil supply system, ensure the movement parts get adequately lubricated to let better durability.

★ (Optional)5+2mm thin plate system, reduce the makeready time.

Technical Parameters