Overview

Essential details

Slider Stroke (mm):

230 mm

Automatic Level:

Fully Automatic

Throat Depth (mm):

350 mm

Machine Type:

Synchronized

Length of Working Table (mm):

2500

Width of Working Table (mm):

140 mm

Dimension:

3750*2180*2950mm

Condition:

New

Place of Origin:

Anhui, China

Brand Name:

accurl

Material / metal Processed:

Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum

Automation:

Automatic

Extra Services:

End Forming

Weight (KG):

5600

Motor Power (kw):

11 kw

Key Selling Points:

High Productivity

Warranty:

3 years

Applicable Industries:

Hotels, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works

Showroom Location:

Canada, United Kingdom, United States, Italy, France, Germany, Indonesia, India, Mexico, Spain, Malaysia

Marketing Type:

Hot Product 2019

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Pump

Control system:

ESA/DElEM/CYBELEC

Main Motor:

Siemens Germany

Bending length:

2500mm

CNC or not:

CNC Bender Machine

USE FOR:

Sheet metal Bending

Bending thickness:

6 Mm

Beam Stroke:

230mm

Daylight:

430mm

Keyword:

Hydraulic Press Break

Application:

Stainless Plate Bending

Supply Ability

Supply Ability

60 Set/Sets per Month

Packaging & delivery

Packaging Details

wooden package for press brake

Port

shanghai port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 60 To be negotiated

Products Description

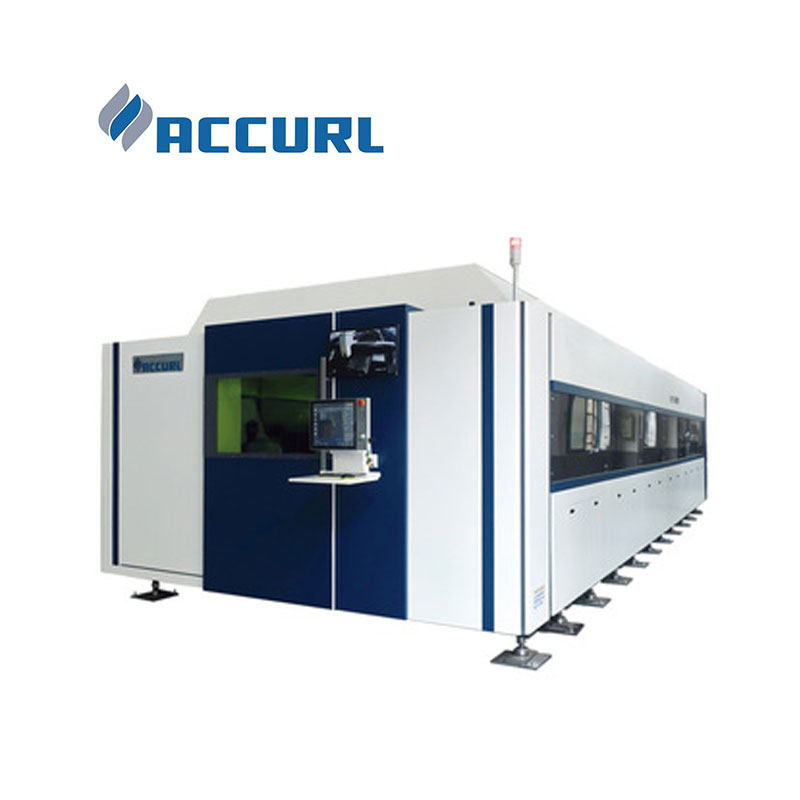

CNC PRESS BRAKE EURO GENIUS SERIES

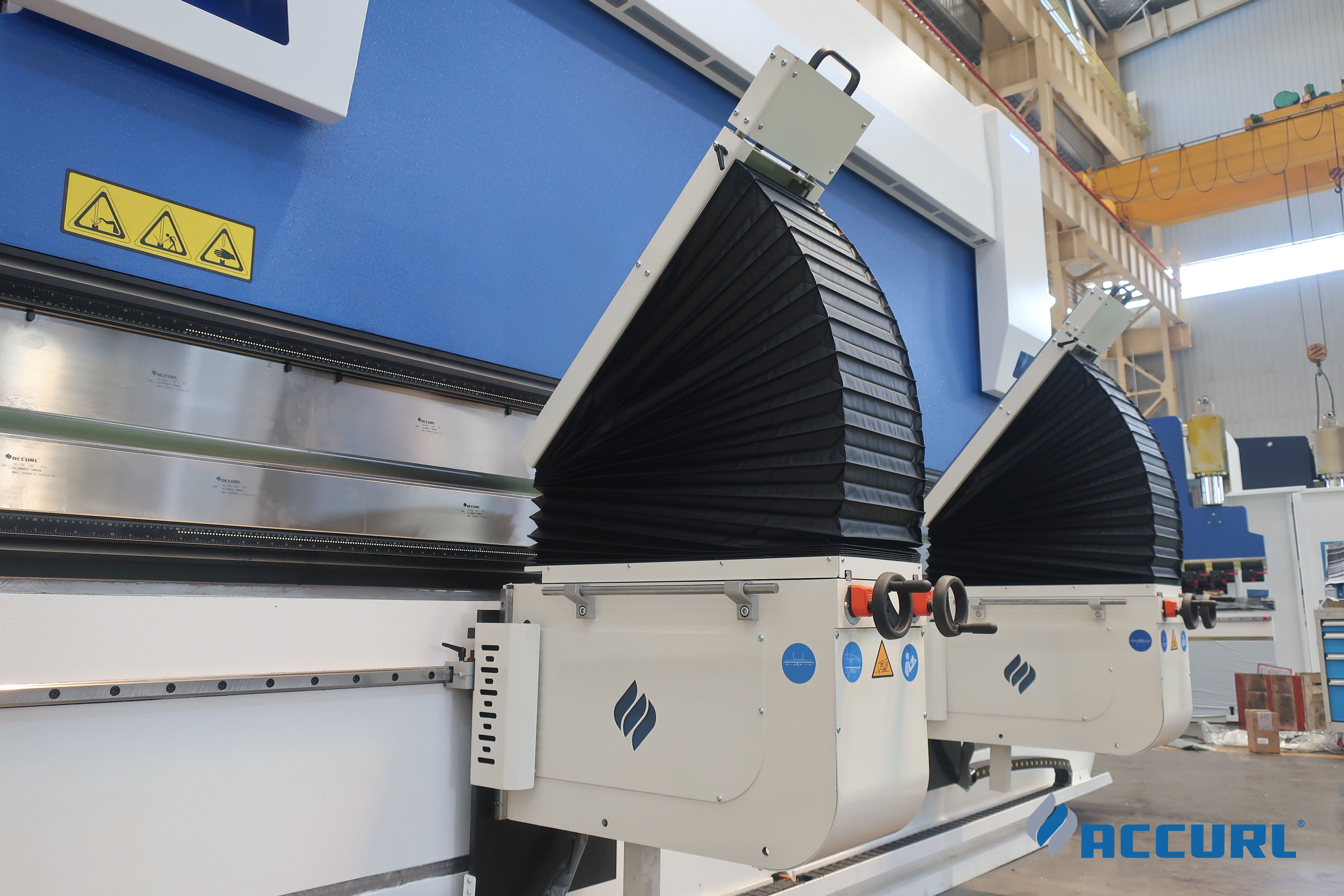

ACCURL® EURO-GENIUS Series press brake features an CNC crowning system for improved quality, a servo driven back gauge system for increased speeds, and 3D capable graphical control unit to simulate bending sequences and collision points.Also has increased working speeds, stroke, daylight, and pressing capacities of GENIUS Series machines. The future - as a result of rising energy costs and increasingly cost efficient speed-controlled drives offered on the market, variable-speed solutions are on the advance.

Details Images

CNC ConTROL SYSTEM

CNC BACKGAUGE

ACCURL press brake are provided are equipped with a backgauge constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning.

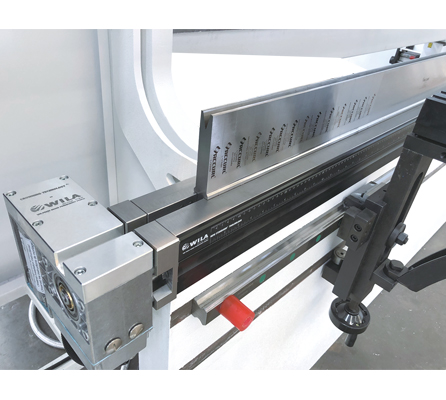

WILA NEW STANDARD AND CLAMPING SYSTEMS

Innovative and super-fast clamping systems for clamping punches to the upper beams of press brakes. The Universal Press Brake Concept (UPB) makes it possible install New Standard and Clamping Systems on any press brake.

WILA NEW STANDARD CROWANG AND HOLDERS

WILA Crowning systems fully compensate for the deflection in press brakes. This results in a consistent bending angle across the entire length of the machine. WILA New Standard Crowning Systems utilize a series of patented adjustable wedges known as Wila Waves.

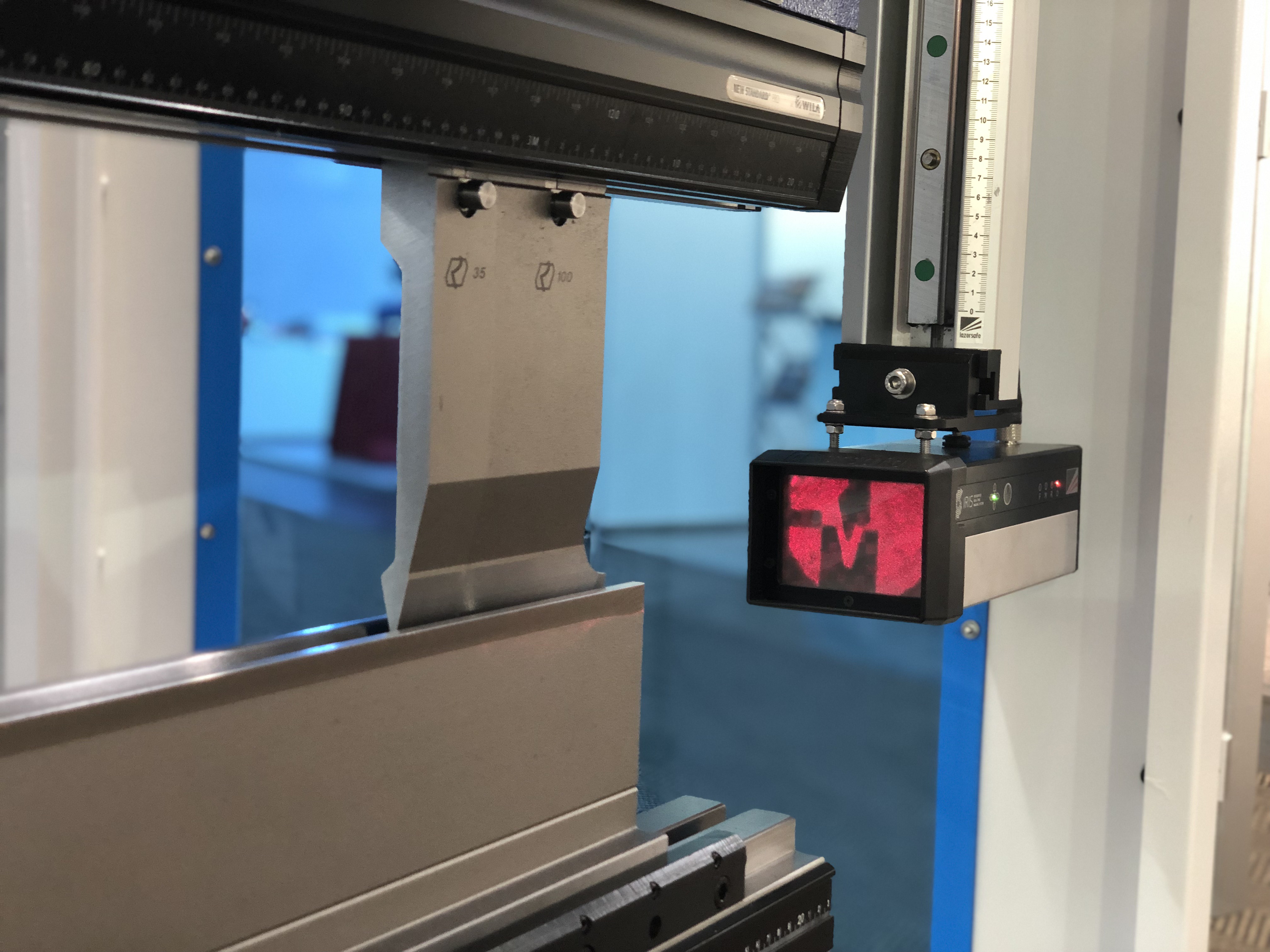

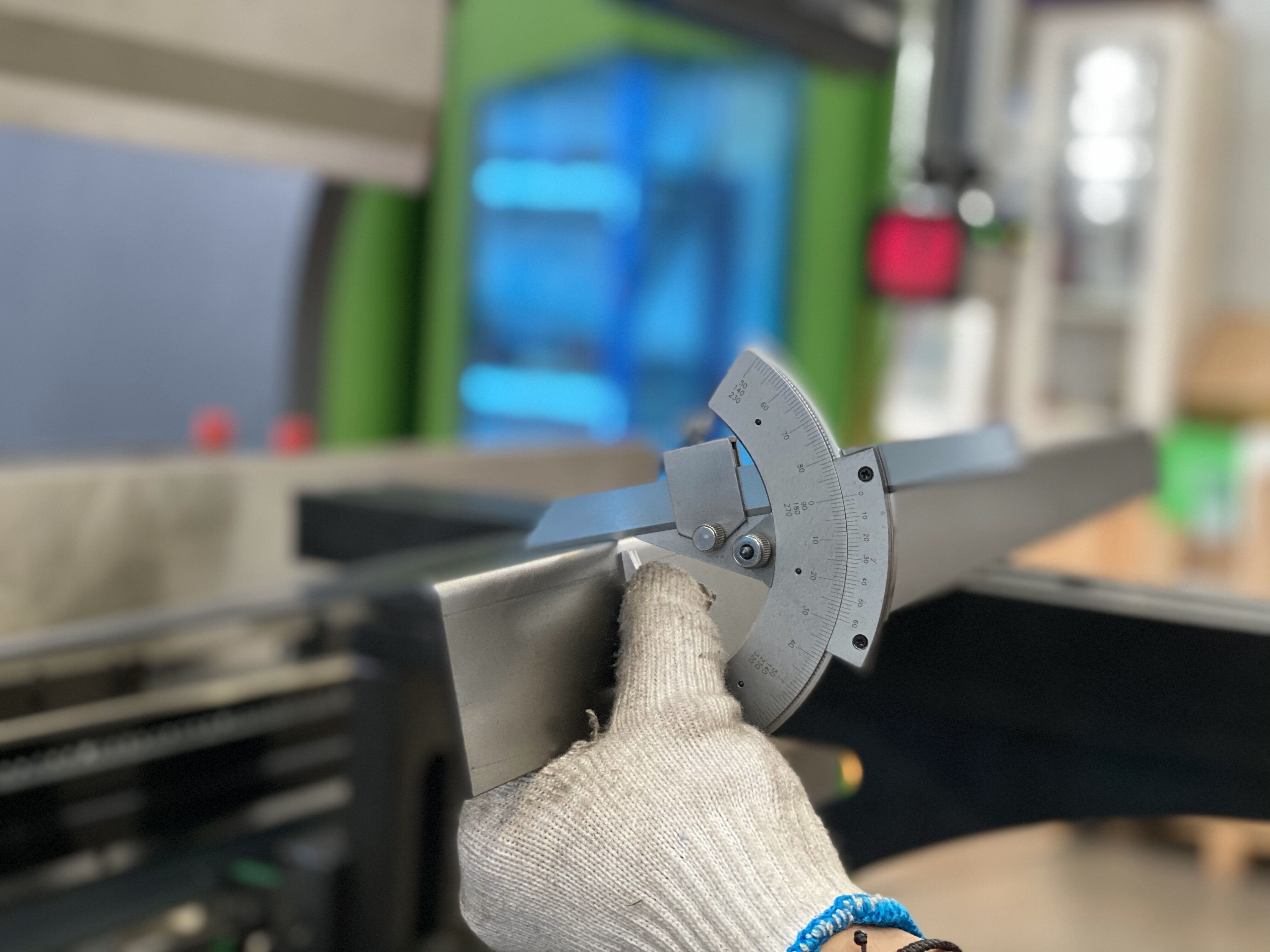

LASER CHECK ANGLE MEASUREMENT

Laser Check, manufactured by Data M Engineering, is a bend angle measurement and correction system by means of a laser beam. The device is made of a laser and a camera on both sides of the bending line. Detection is carried out in this way.

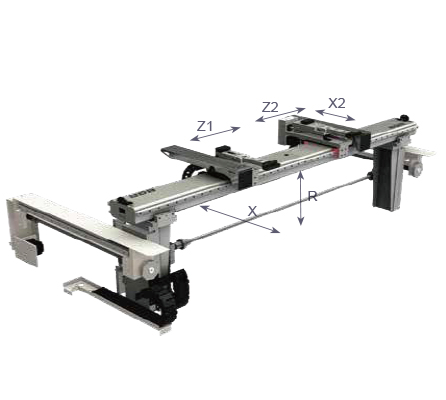

CNC FOLLOWER SUPPORTS AP1 + AP2

It basically consists of a pair of sheet supports placed on the front of the machine at the height of the bending line (bottom tool). Supports are controlled by the CNC, following and supporting the sheet during the bending process.

LAZERSAFE OPTICAL SAFETY GUARDS

Performance without compromise. ACCURLuse LazerSafe LZS-LG-HS guarding system offers a highly effective solution for both operator safety and machine productivi- ty.Designed for use with Lazer Safe's PCSS A Serice, the Lazersafe is category 4 compliant and meets the world’s most demanding international safety standards(CE Certified Category 4 Safety Controller with integrated)。

Related Products

1KW Fiber Laser Cutting Machine

Hydraulic Guillotine Shearing Machine

Handheld Laser Welding Machine

Company Profile

Why choose us?

ACCURL is a famous manufacturer of metal sheet equipments in world market. Its Brand ¡°Accurl¡± has been leading brand for many years in the field of international metal sheet equipments. Our group devote ourselves to product development, production and sales.

Our main products are: CNC Press Brake, Shears, Hydraulic press, Laser Cutter and CNC rolling machine these sheet metal processing equipments.we are using advanced technology from German, Japan, and Italy.we can produce large Hydraulic Press and Press Brake more than 16000 ton & 16m.we are with professional R&D team, and we have World-class design and manufacturing capabilities.

Technological Process

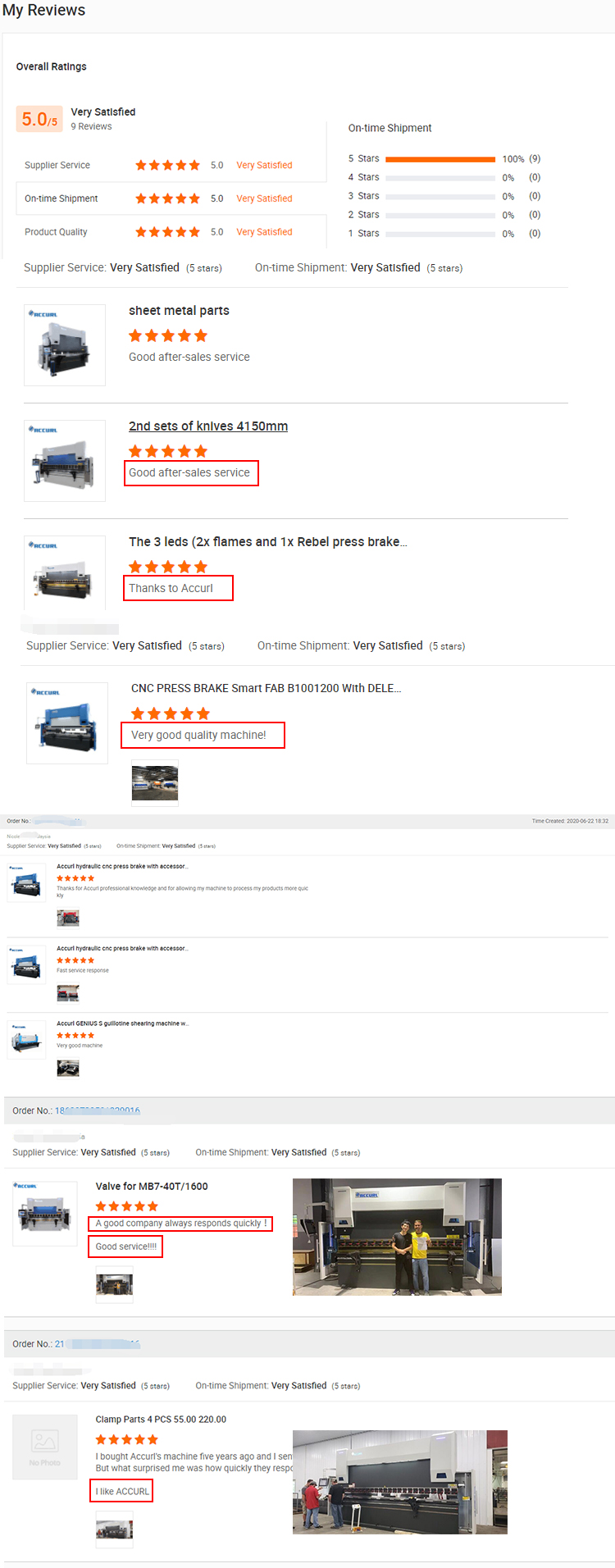

We got 5 stars rating!

Exhibition

Production Power

The Robot Arm of the Press Brake

OEM Press Brake

OEM Press Brake

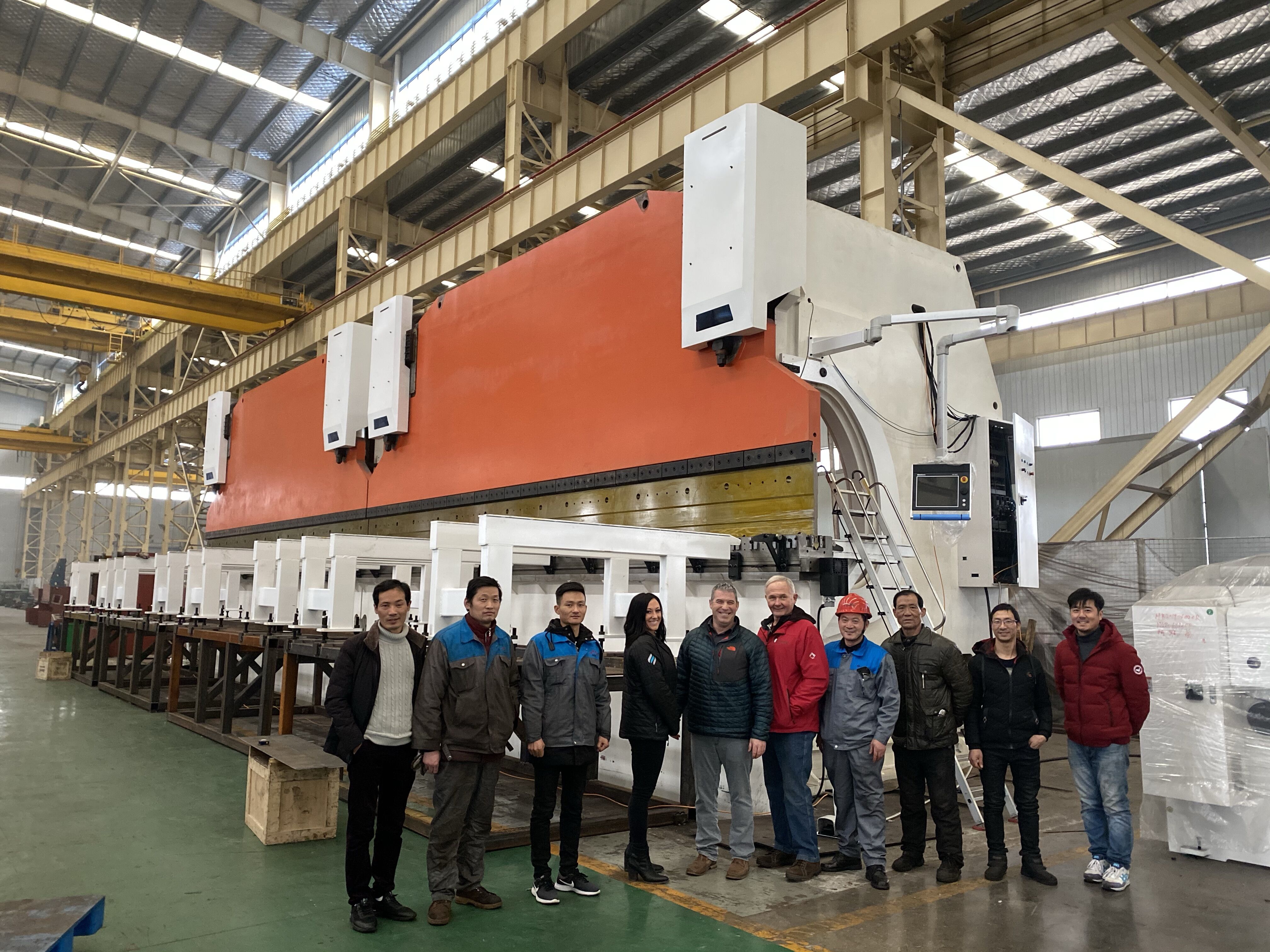

Our American dealers came to visit the factory

Product packaging

1.Our wooden case is after fumigation treatment. Needn't timber inspection, saving shipping time. 2.All the spare parts of the machine were covered by the some soft materials mainly using pearl wool.

3.The outmost is wooden case with fixed formwork. 4.The bottom of the wooden case has firm iron jack, convenient to handing and transport.

Our Serives

QUALITY CONTROL

Nearly 50 years of expertise in the manufacture of press brakes and guillotines machines give us the security that is needed for future challenges. High standards of quality and a team with the best training and knowledgeare a major condition for our success. Our products are the result of a continued focus on improving internal processes underpinned by high quality levels, that result in the recognition ofAccurl' s machines as quality garantee equipment.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

FAQ

1.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment.

The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

3.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone’s satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high quality export packaging. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature sensitive items. Specialist packaging and non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information.