Min quantity:1Piece

Quantity:999Piece

Deliver:In 3 days

Overview

Essential details

Slider Stroke (mm):

200 mm

Automatic Level:

Fully Automatic

Throat Depth (mm):

400 mm

Machine Type:

Synchronized, Press Brake

Length of Working Table (mm):

3200

Width of Working Table (mm):

100 mm

Dimension:

3850*1530*2520mm

Condition:

New

Place of Origin:

Anhui, China

Brand Name:

AccurL

Material / metal Processed:

Brass / Copper, Stainless steel, ALLOY, Carbon steel, Aluminum

Automation:

Automatic

Extra Services:

End Forming

Weight (KG):

6500

Motor Power (kw):

7.5 kw

Key Selling Points:

Automatic

Warranty:

3 years

Applicable Industries:

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works

Showroom Location:

United Kingdom, United States

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

2 years

Core Components:

Bearing, Motor, Pump, Gear

Raw Material:

Sheet / Plate Rolling

CNC Control Axis:

Y1 + Y2 + X + W-axis Crowning

Electrical components:

Schneider Electrical from French

Motor Power:

Siemens from Germany

BackGauge & RAM Drive:

Inverter from Schneider Electrical

Ball screw/ Polished rod:

HIWIN from TaiWan Brand

Keyword:

cnc press brake machine

Application:

Stainless Plate Bending

Control system:

DA66T

Certification:

ce

After-sales Service Provided:

Video technical support, online support

After Warranty Service:

Video technical support, online support

Local Service Location:

United Kingdom, United States

Supply Ability

Supply Ability

60 Set/Sets per Month

Packaging & delivery

Packaging Details

cnc press brake,wooden package or can be adjust for the machine's safety

Port

Shanghaiport

Picture Example:

Products Description

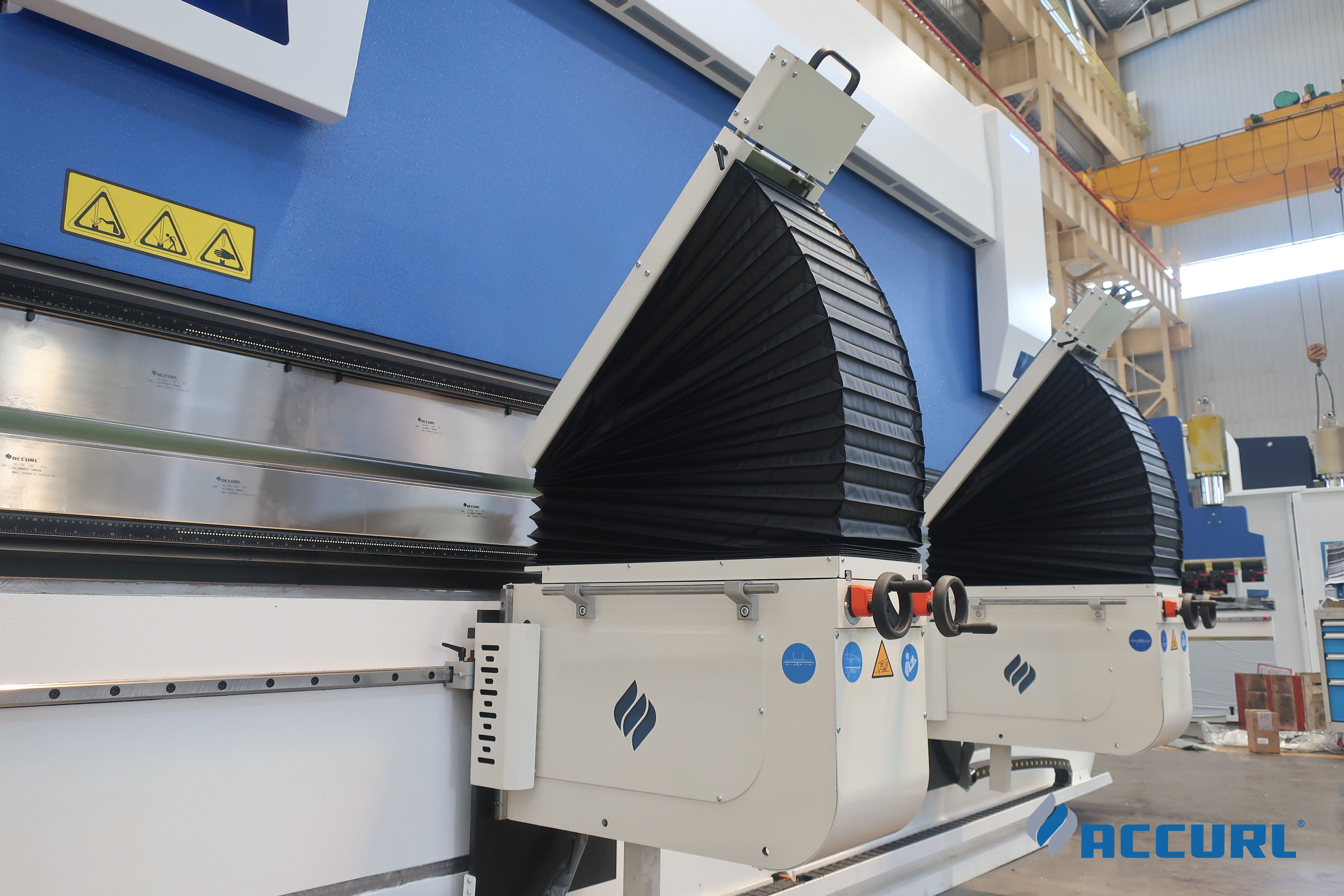

CNC PRESS BRAKE EURO GENIUS SERIES

ACCURL® EURO-GENIUS Series press brake features an CNC crowning system for improved quality, a servo driven back gauge system for increased speeds, and 3D capable graphical control unit to simulate bending sequences and collision points.Also has increased working speeds, stroke, daylight, and pressing capacities of GENIUS Series machines. The future - as a result of rising energy costs and increasingly cost efficient speed-controlled drives offered on the market, variable-speed solutions are on the advance.

Details Images

CNC ConTROL SYSTEM

CNC BACKGAUGE

ACCURL press brake are provided are equipped with a backgauge constituted by a solid structure in order to assure the best repetitiveness and high precision in axes positioning.

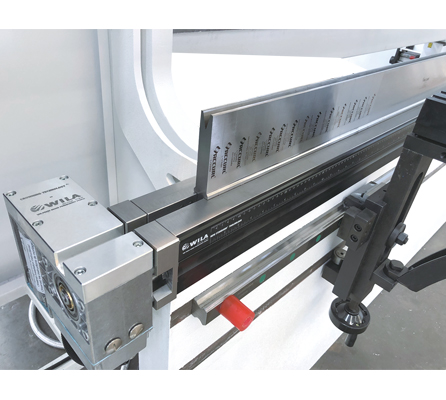

WILA NEW STANDARD AND CLAMPING SYSTEMS

Innovative and super-fast clamping systems for clamping punches to the upper beams of press brakes. The Universal Press Brake Concept (UPB) makes it possible install New Standard and Clamping Systems on any press brake.

WILA NEW STANDARD CROWING AND HOLDERS

WILA Crowning systems fully compensate for the deflection in press brakes. This results in a consistent bending angle across the entire length of the machine. WILA New Standard Crowning Systems utilize a series of patented adjustable wedges known as Wila Waves.

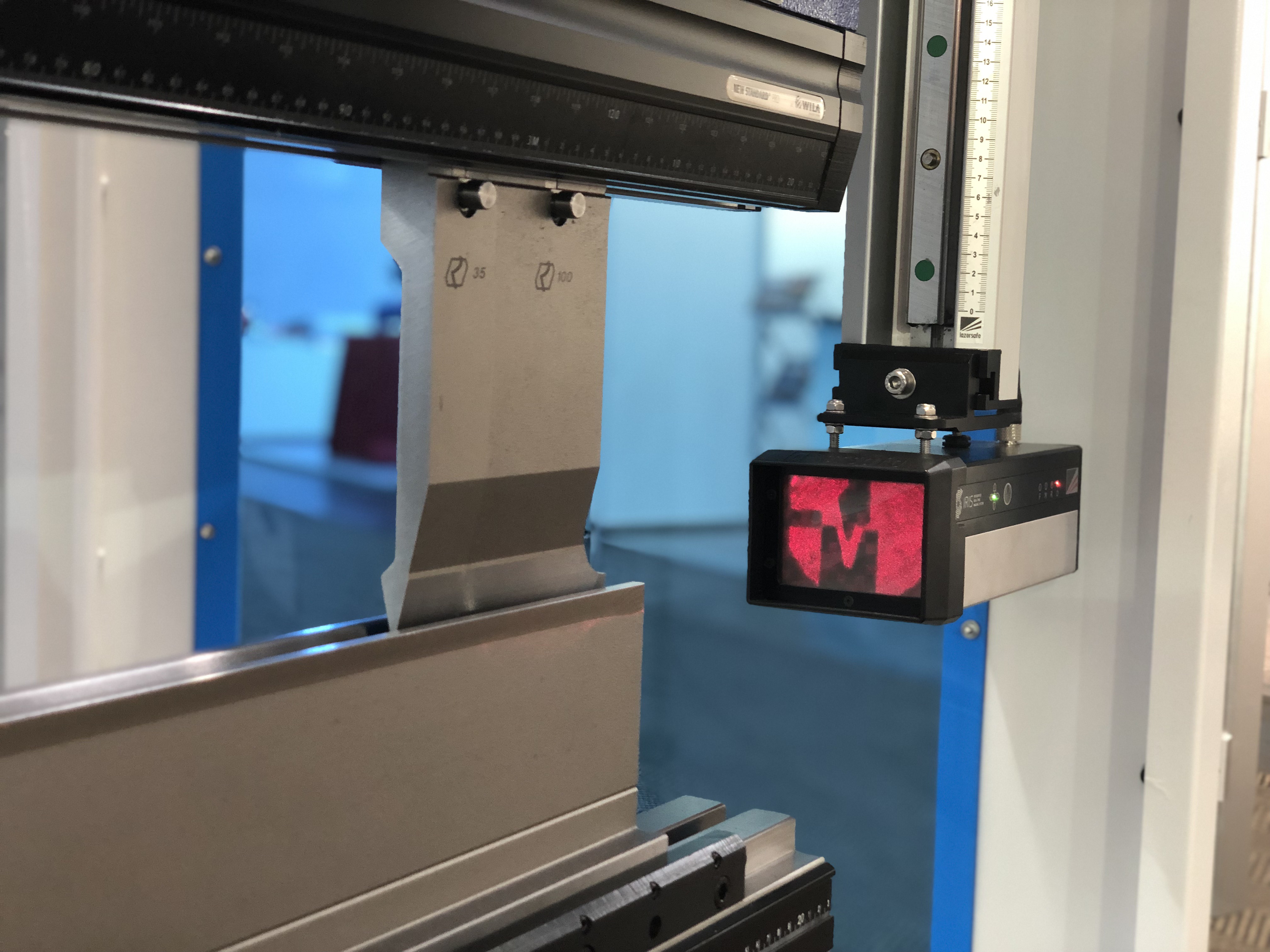

LASER CHECK ANGLE MEASUREMENT

Laser Check, manufactured by Data M Engineering, is a bend angle measurement and correction system by means of a laser beam. The device is made of a laser and a camera on both sides of the bending line. Detection is carried out in this way.

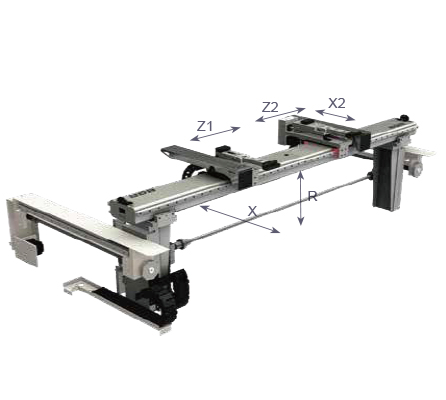

CNC FOLLOWER SUPPORTS AP1 + AP2

It basically consists of a pair of sheet supports placed on the front of the machine at the height of the bending line (bottom tool). Supports are controlled by the CNC, following and supporting the sheet during the bending process.

LAZERSAFE OPTICAL SAFETY GUARDS

Performance without compromise. ACCURLuse LazerSafe LZS-LG-HS guarding system offers a highly effective solution for both operator safety and machine productivi- ty.Designed for use with Lazer Safe's PCSS A Serice, the Lazersafe is category 4 compliant and meets the world’s most demanding international safety standards(CE Certified Category 4 Safety Controller with integrated)。