Overview

Essential details

Applicable Industries:

Manufacturing Plant

Showroom Location:

Brazil, Peru, Saudi Arabia, Indonesia, India, Mexico, Russia, Spain

Condition:

New

Machine Type:

Bag Forming Machine

Bag Type:

Pouch Bag

Material:

Plastic

Computerized:

Yes

Place of Origin:

Zhejiang, China

Brand Name:

Wity

Model Number:

C+FD

Voltage:

380V

Dimension(L*W*H):

12300*2050*2000mm

Weight:

4500kg

Warranty:

1 Year

Key Selling Points:

Multifunctional

Marketing Type:

Ordinary Product

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor

Max Speed:

35M/MIN

Max length of bag making:

380mm

Max width of bag making:

580mm

Dimension of roll material:

600*1200mm

Accuracy of orientation:

≤± 0.5mm

Speed of machine:

150 hypo-minute

Speed of feeding:

Max: 35 m/min

Quantity of temperature heating:

22

Bound of temperature:

0-300 ℃

After Warranty Service:

Video technical support, online support, Spare parts, Field maintenance and repair service

Local Service Location:

Brazil, Peru, Saudi Arabia, Indonesia, India, Mexico, Spain

After-sales Service Provided:

online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Supply Ability

Supply Ability

30 Set/Sets per Month

Packaging & delivery

Packaging Details

Stretch film or wooden package

Port

Ningbo port

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 60 To be negotiated

online Customization

Click the image below to start online customization for the design you want.

Customise Now

Video Description

Product Description

Pouch bag making machine

This machine can do for three side sealing, zipper bag ,stand up bag (single sheet film folded material and normal stand up bag with another small piece film gusset )

Specification

Features

Three servo motor for traction from JAPA PLC adopts Panasonic from Japan; Touch Screen from Taiwan Main driving is alternating current with Yaskawa from JAPAN inverter, automatic constant tension for unwinding. Thermal-sealing knife’s quantity of heat: 1. Vertical-sealing for zipper adopts 1 group for heating fluctuation, 2. Vertical-sealing for side sealing adopt 5groups for heating fluctuation, cooling fluctuation from up and down 3. Zipper flattening adopt 2 groups heating. 4. Bottom sealing adopts 3 group heating, 1 group for cooling

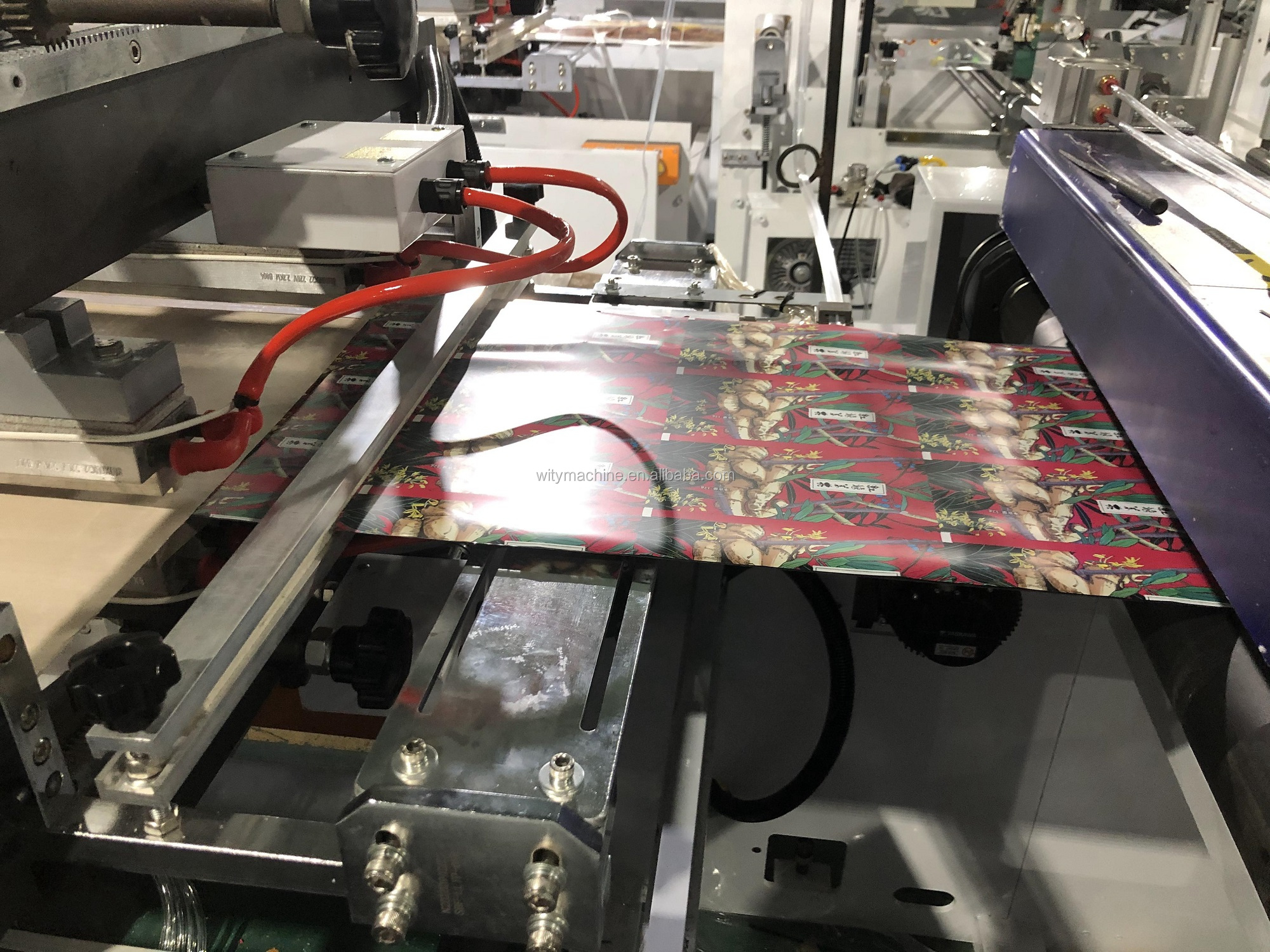

Details Images

Unwinder part

Folding part

Web-guiding sensor

Bottom film hole punching

Film separating

Zipper feeding

Third film unwinder

Perforation unit

Printed mark sensor