Min quantity:1Piece

Quantity:999Piece

Deliver:In 7 days

Overview

Essential details

Applicable Industries:

Garment Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Food Shop, Food & Beverage Shops

Showroom Location:

Egypt, Turkey, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, India, Spain, Thailand, Chile, UAE, South Africa, Ukraine, Uzbekistan, Malaysia, Morocco

Condition:

New

Machine Type:

Bag Forming Machine

Bag Type:

Heat cutting side sealing bag

Material:

Plastic

Computerized:

Yes

Place of Origin:

Zhejiang, China

Brand Name:

WITY

Model Number:

DRQ-S800

Voltage:

380V/3P

Dimension(L*W*H):

5800*1550*1750mm

Weight:

1700KG

Warranty:

one year

Key Selling Points:

High Productivity

Marketing Type:

New Product 2020

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, Pump, PLC, Gearbox

After-sales Service Provided:

Engineers available to service machinery overseas

Size:

800mm

Speed:

220pcs/min

Machine color:

Green

Function:

PE, BOPP, POF,CPP bags

Controller:

SYMAC

Photocell:

Panasonic brand

Puncher:

1pcs

Sealing knife:

Straight Sealing Knife

Touch screen:

Movable

After Warranty Service:

Video technical support, online support, Spare parts

Local Service Location:

Egypt, Turkey, Viet Nam, Philippines, Peru, Saudi Arabia, Indonesia, Spain, Thailand, Malaysia, Morocco, UAE, Sri Lanka, South Africa, Ukraine, Uzbekistan

Certification:

No

Supply Ability

Supply Ability

30 Set/Sets per Month

Packaging & delivery

Packaging Details

Stretch film package

Port

Ningbo/Shanghai

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

Video Description

Wity Machinery

Product Description

This machine is suitable for various kind of material such as BOPP, CPP, LDPE, HDPE, POF & laminated film,etc, which with printed or without printed. It is a kind of ideal equipment for making Stationery bag, ornaments bag, garment Bag, food bag and hang bag.

Features

1.Touch screen operating, SYMAC movement control, easy operation 2.The main motor speed, traction speed and unwinding speed synchronization controlled. 3.The whole machine adopts servo motor drive. 4.Accurate tracking printing pattern, automatic stop and alarm when missing printed mark. 5.Pneumatic puncher, the punching position can be adjusted independently. 6.Main motor controlled by frequency inverter, easy operation and reduce power consumption. 7.Automatic counting, can preset the stack number according request quantity. 8.Firm and smooth bag sealing .

Specification

Bag Details

Sample Pictures

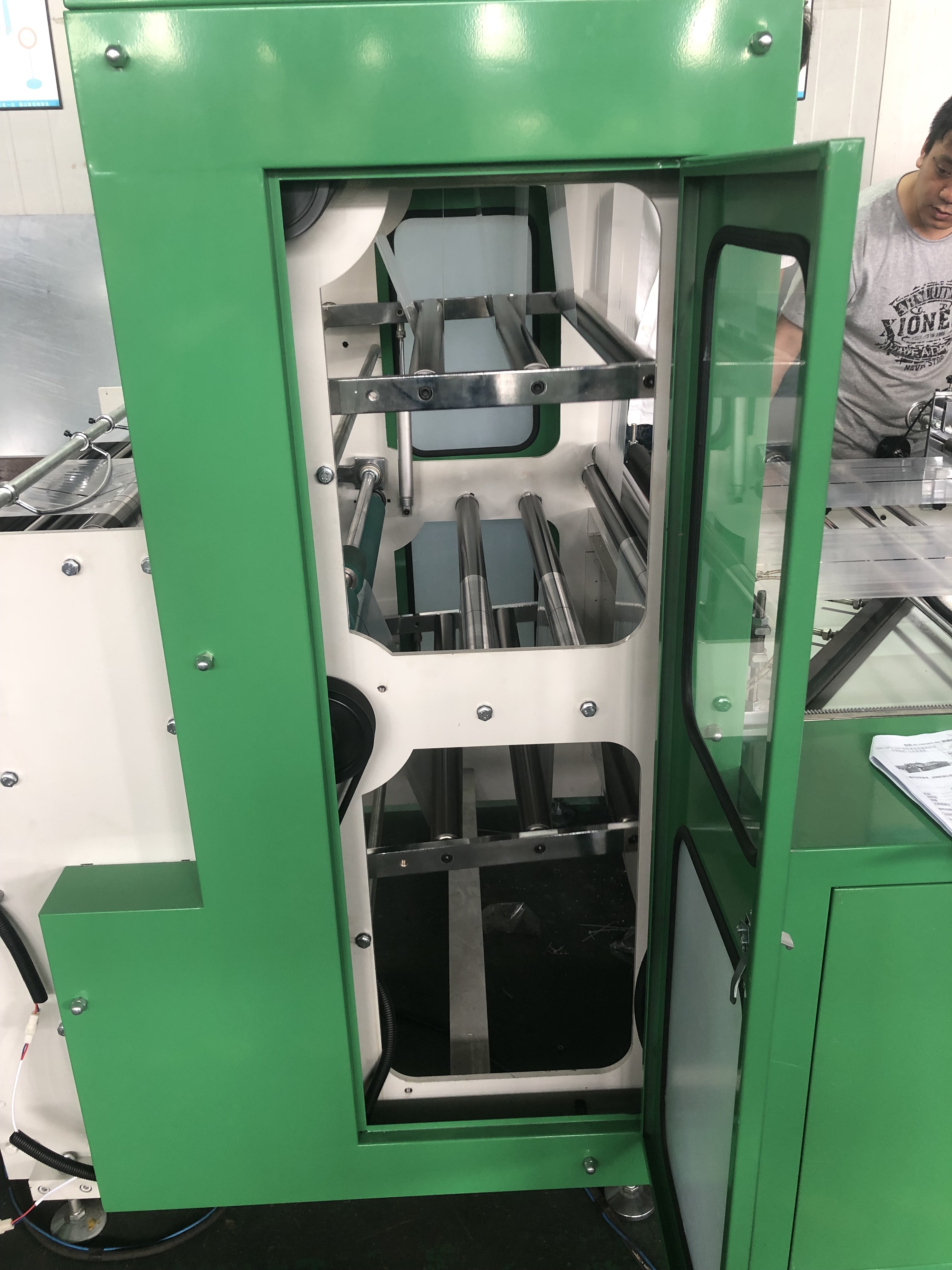

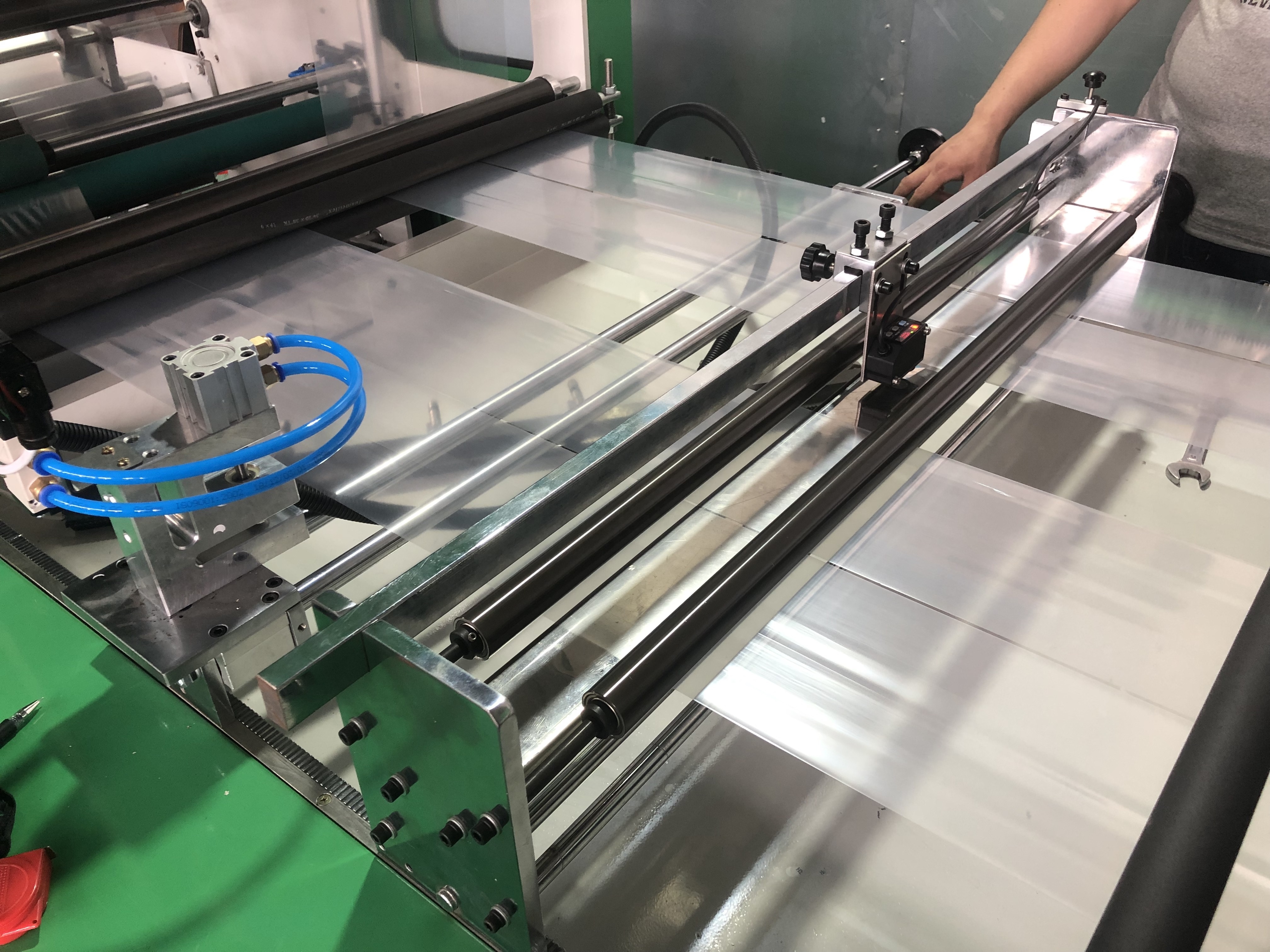

Detailed Images

Double Unwinders with 2 sets of Slitting Knife

Dancing Rollers

Hole Puncher & Photocell for Printed Mark Tracking